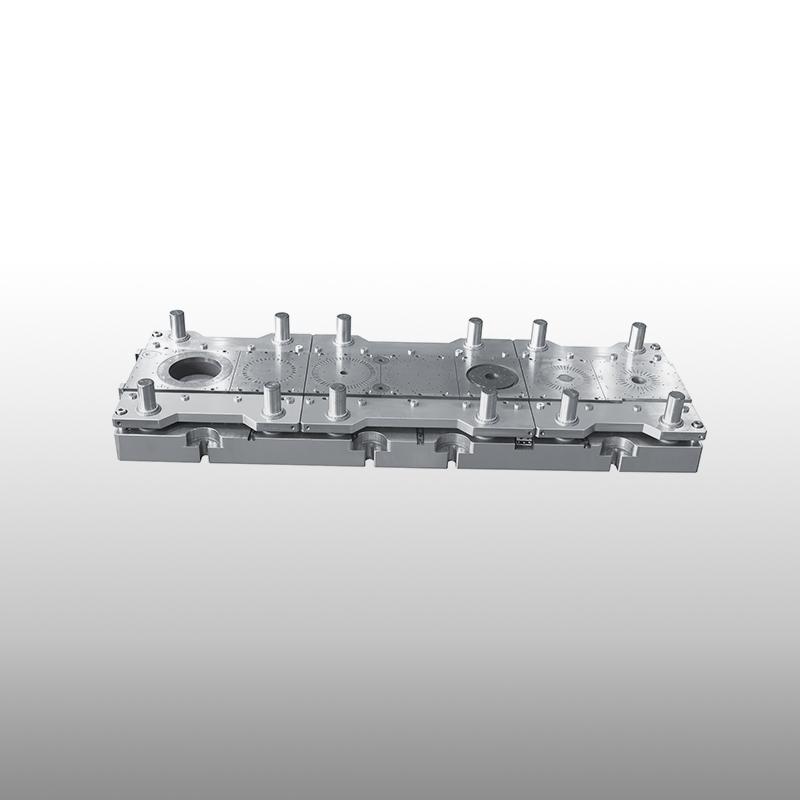

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posted 2025-01-15 07:40:32

0

117

Site içinde arama yapın

Kategoriler

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Electrifying Carpentry Advancements Reshaping the Landscape of Woodcraft

In the ever-evolving field of carpentry, innovation plays a pivotal role in enhancing efficiency,...

LAFC 2, LA Galaxy 0

Carlos Velascored a late function inside his return in the direction of stage andLAFC took a 2 0...

How to Take Care of 4c Edges Lace Wig

One of the most frequent questions online and buzzing around social media is how to properly care...

Make Gold Fast by Opening Boxes in Diablo 4

Hey there, fellow treasure hunters! If you're like me, you’ve probably spent hours...

The Ultimate Guide to LED Round Ceiling Lights: Everything You Need to Know

Understanding the Basics of LED Round Ceiling Lights

Ok, so let's look over here led round...