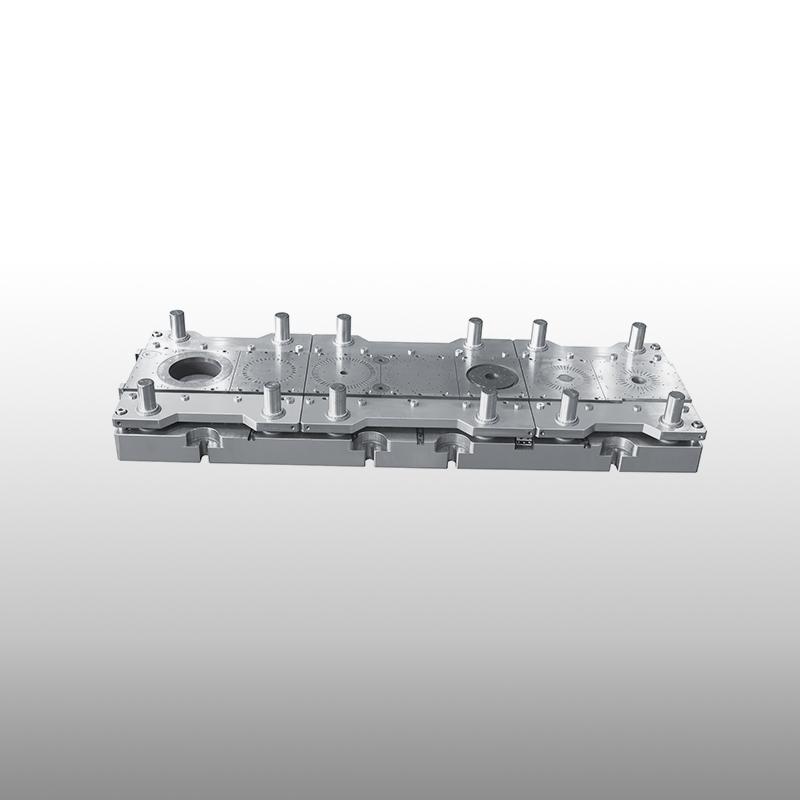

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posted 2025-01-15 07:40:32

0

121

Rechercher

Catégories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

A Complete Guide to Diamond Earrings: Timeless Elegance for Every Occasion

Diamond earrings are the epitome of timeless elegance and sophistication. Whether you’re...

How Stainless Steel Rims Improve Motorcycle Handling

Stainless steel motorcycle rims are essential components that play a crucial role in...

How to Find Jobs in Karachi via Online Portals

Introduction

Finding jobs in Karachi, one of Pakistan's largest and most dynamic cities, has...

Sentiment Analytics Market Key Players, Dynamics, Insights By 2032

Sentiment Analytics Market: A Comprehensive Overview

The sentiment analytics market is...

Strategic Positioning of Top 5 in Airborne SATCOM Market

Polaris Market Research announces the release of its latest research study on Airborne...