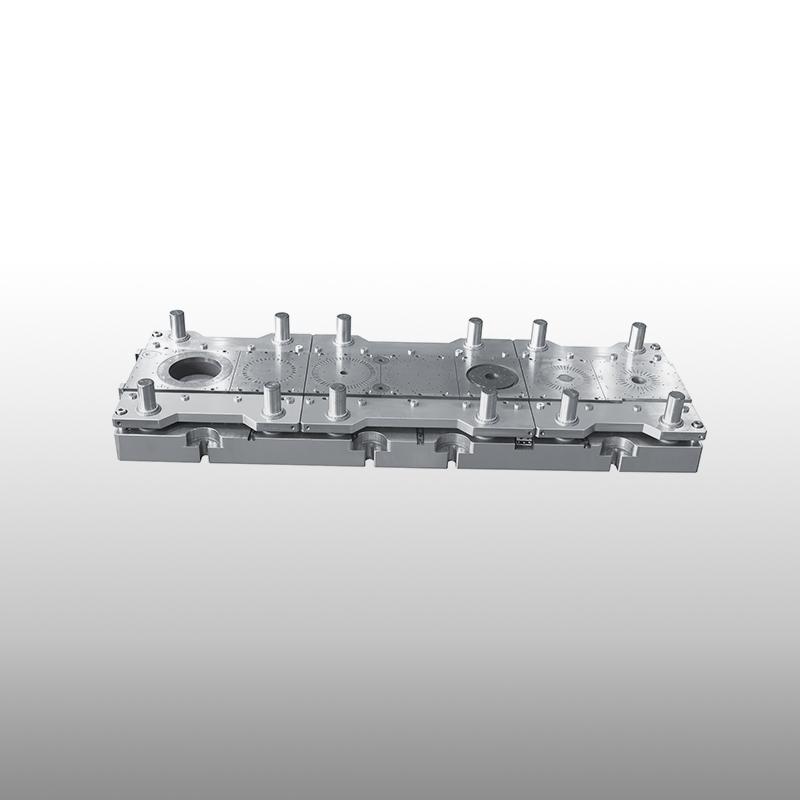

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

- ИЗБРАННОЕ

- Новости

- ИССЛЕДОВАТЬ

- Страницы

- Группы

- Мероприятия

- Статьи пользователей

- Marketplace

- Offers

- Jobs

- Форумы

- Кинозал

- Игры

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Сообщение 2025-01-15 07:40:32

0

210

Поиск

Категории

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Больше

Management Programs in Corporate Success Through Soft Skills Development

In today’s evolving business environment, technical expertise alone is not enough to ensure...

Electronic Toll Collection Market Gains Speed with Smart Infrastructure

Market Overview

The global electronic toll collection market was valued at USD 9,492.07...

Beyond Cleaning: Proactive Strategies to Banish Mold From Your Home

Few things are more frustrating to the average homeowner than having to deal with mold....

Chrome Hearts Hoodie: The Ultimate Flex of Street-Luxe Culture

In a world where fashion is as much about attitude as it is about aesthetics, few brands hold the...

Buy Ethernet Cable Online in UK – Best Options & Buying Guide (2024)

Whether you're setting up a home network, upgrading your office, or optimizing your gaming setup,...