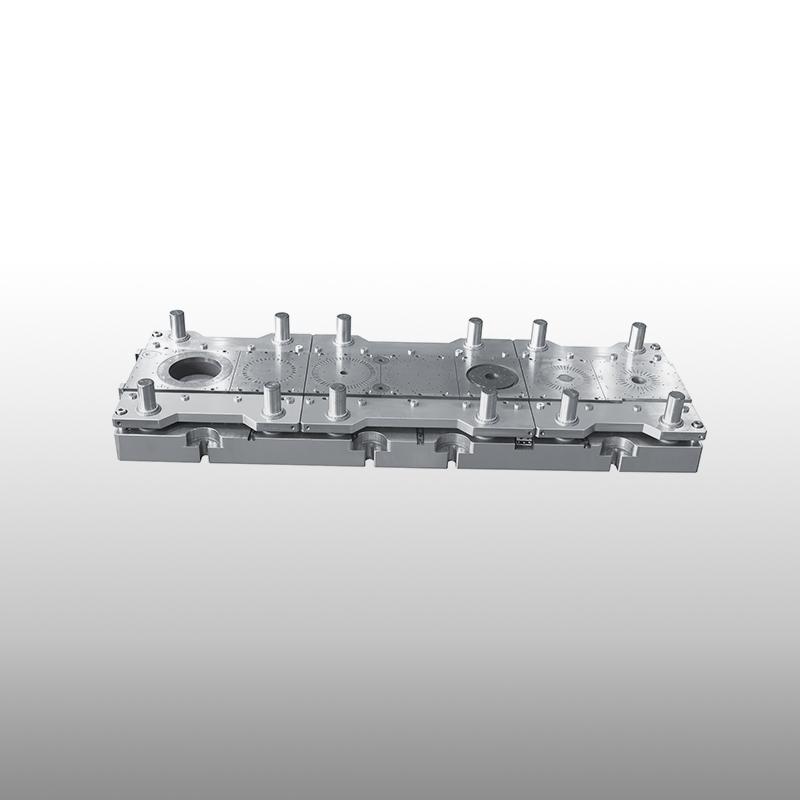

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Postado 2025-01-15 07:40:32

0

123

Pesquisar

Categorias

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leia mais

Essential Aspects of IP Testing Equipment

IP Testing Equipment: A CompreheIP Testing Equipmentng>The term IP Testing Equipment refers to...

Urwerk men watch Replica UR-110 Black

Dream of the actual Blue Planet|URWERK UR-100V Blue Planet Limited Edition...

Electronic Wet Chemicals Market Set to Dominate with Breakthrough Innovations by 2032

The global Electronic Wet Chemicals Market is on an upward trajectory, driven by the...

B2B Telecommunication Market Size, Industry Share, Forecast, 2032

B2B Telecommunication Market Overview:

The global B2B telecommunication market is poised to...

India Naphtha Market Size Comprehensive Research Methodology, Key Insights-2027

India region held the highest share in 2021.

India Naphtha Market size is expected to reach...