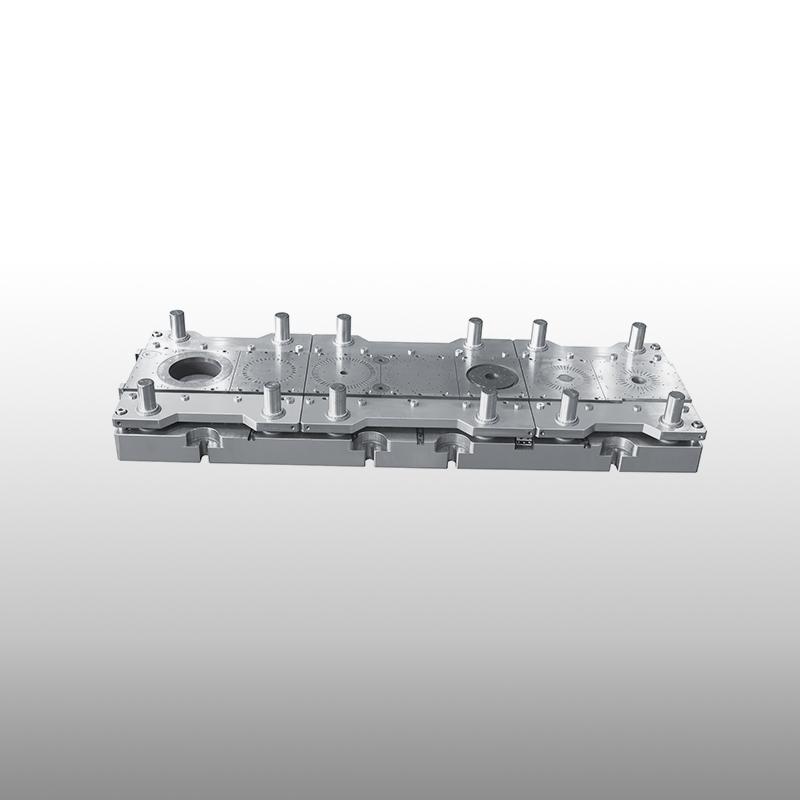

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posted 2025-01-15 07:40:32

0

209

Căutare

Categorii

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Citeste mai mult

Asia-Pacific Medical Robots Market Forecast, Trends & Demand Analysis 2024-2030

Market Overview:

This report presents an extensive evaluation of the Asia-Pacific Medical...

Gastrointestinal Videoscopes Market Trends, Demand, Growth and Competitive Outlook

Gastrointestinal Videoscopes Market, By Application (Bronchoscopy, Arthroscopy, Laparoscopy,...

Lost Ark October update celebrates Halloween with a haunted house

Lost Ark October update celebrates Halloween with a haunted house

The Lost Ark October Update is...

How to get the best gaming experience on kheloyar site get now

Introduction to the game

kheloyar is here to bring revolution on how we think about playing...

Electric Motors Household Appliances Sectors: Growth Forecast and Trends with a 5.87% CAGR

Global electric motors household appliances market is driven by the increasing demand for...