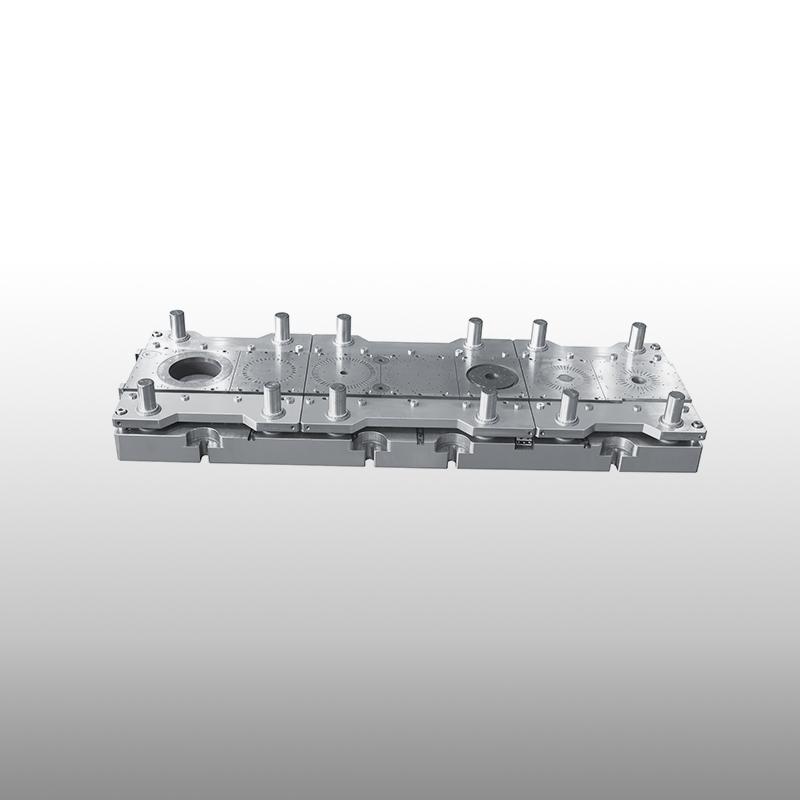

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Postado 2025-01-15 07:40:32

0

118

Pesquisar

Categorias

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leia Mais

Bears name Justin Fields permanent starting quarterback over Andy Dalton for rest of 2021

The franchise officially belongs in the hands of , who was named the starting quarterback going...

Exactly what are some examples of non-fungible tokens?

3) The dApp. An NFT is created that is an item that is used as a proxy for ability in a...

A Comprehensive Guide to Atomic Absorption Spectrophotometers

In the realm of analytical chemistry, atomic absorption spectrophotometry (AAS) stands as a...

10 Prototyping Methods: Turning Ideas into Reality

The journey of new product development is fraught with challenges, and prototyping stands as a...

Hybrid Integration Platform Market foreseen to grow exponentially over 2024-2032

Market Overview

The hybrid integration platform market is experiencing significant...