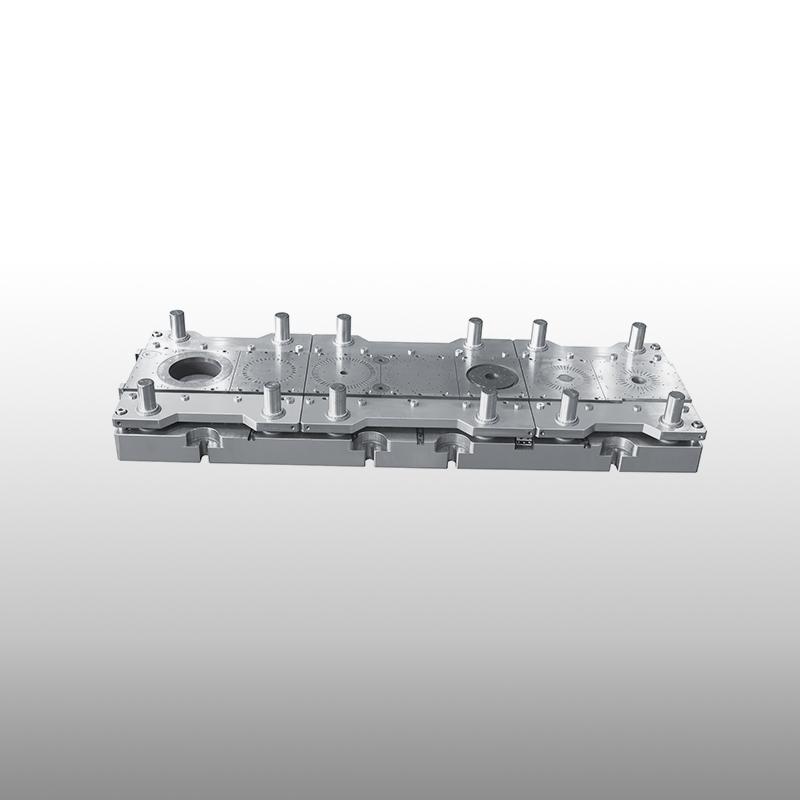

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posted 2025-01-15 07:40:32

0

214

Search

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Eric Emanuel Shorts: A Love Letter to Urban Culture

Urban culture has long been a melting pot of creativity, expression, and style. Among the many...

Clinical Oncology NGS Market Thrives with Precision Medicine and Cancer Genomics Advancements

"Executive Summary Clinical Oncology Next Generation Sequencing Market :

Data Bridge...

The Comprehensive Guide to Impact Test Equipment

Impact Test Equipment: Impact Test Equipmential TestingImpact test equipment is a crucial tool in...

A Guide to London's Traffic Courts: What to Expect and How to Win

Your Question: "I've received a summons to a Magistrates' Court in London for a driving offence....

Exploring the Advantages of Using a Dual Zone Air Fryer Oven in Your Daily Cooking

When it comes to modern kitchen appliances, the dual zone air fryer oven has been gaining...