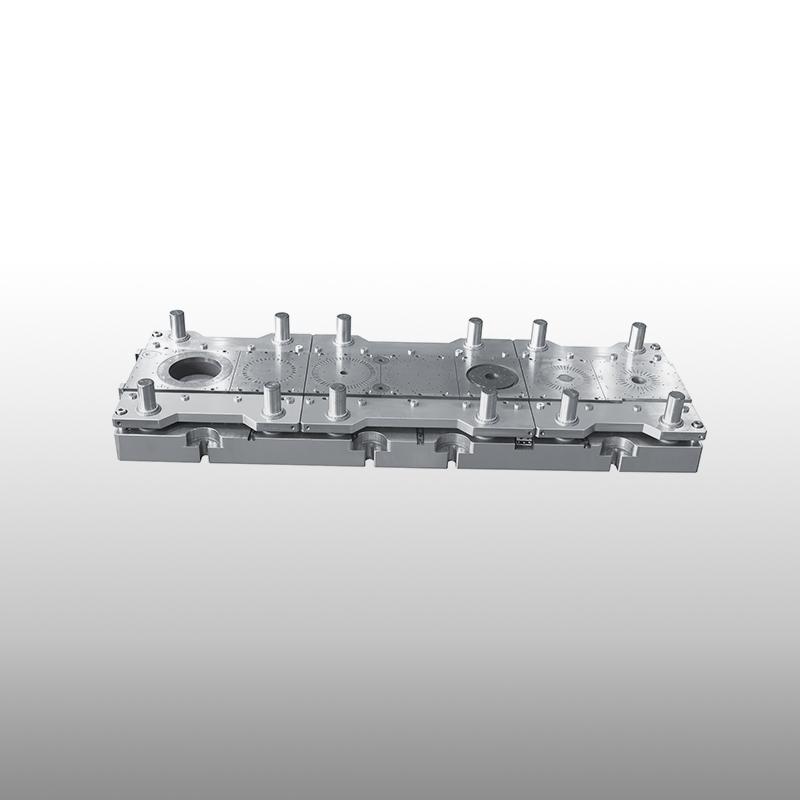

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posted 2025-01-15 07:40:32

0

128

Zoeken

Categorieën

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Air Conditioner Manufacturers in UAE: Leaders in Cooling Solutions

The UAE, with its extreme temperatures and scorching summers, has an ever-growing demand for...

Health And Safety Concerns Surrounding Sex Doll Usage

Sex dolls have become increasingly popular, but like any other intimate product, their use comes...

From Rookie to Pro: How Swimming Ear Plugs Improve Performance in the Water

Swimming is a popular sport and recreational activity that offers numerous benefits for...

Applications and Advantages of Electric Submersible Sludge Pumps

The electric submersible sludge pump is a specialized pump designed for handling slurry, sludge,...

Коллекция игр в online игорном заведении Лев

Игорный салон "Lev" - довольно известная виртуальная платформа, которая завоевала доверие...