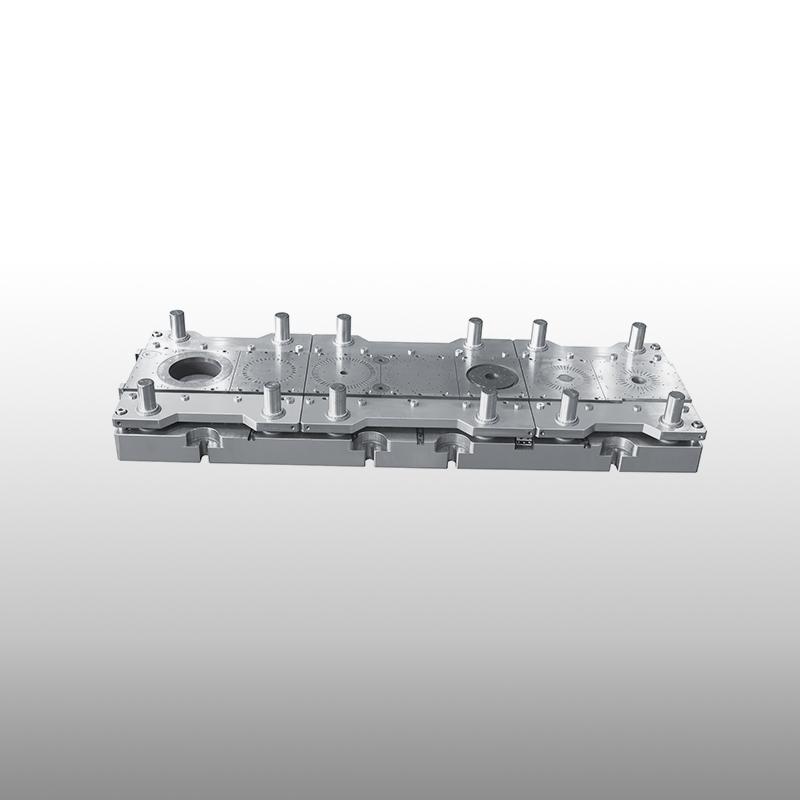

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posted 2025-01-15 07:40:32

0

215

Buscar

Categorías

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Essentials Hoodie – The Ultimate Style and Comfort Staple

Introduction to Essentials Hoodie

When it comes to modern streetwear,...

The Essential Guide to Portable Solar Lights

With the escalating global embrace of sustainable and eco-friendly energy alternatives, portable...

US Rockwool Market Segmentation by Application & End-Use Industry

Sustainability is no longer an option; it is a necessity for the US construction sector. As...

Everything You Should Know About Construction Project Management in Austin, TX

Austin, TX, is experiencing rapid growth, making construction management an essential element for...

E-Drive Axle Gear Shifting Actuator Market size and Key Trends in terms of volume and value 2030

E-Drive Axle Gear Shifting Actuator Market was valued at USD 13.39 Bn. in...