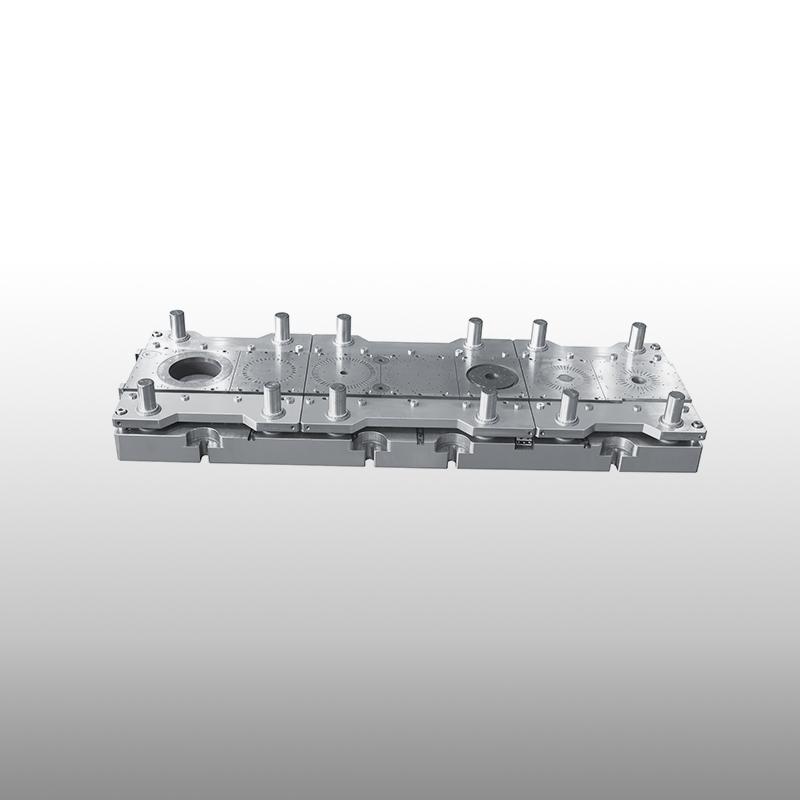

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

- FAVORITEN

- NEUIGKEITEN

- EXPLORE

- Seiten

- Gruppen

- Veranstaltungen

- Blogs

- Marktplatz

- Angebote

- Jobs

- Foren

- Filme

- Spiele

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posted 2025-01-15 07:40:32

0

126

Search

Nach Verein filtern

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Tail-Waggin' Style: Crafting the Perfect Custom Pet Sweatshirt

In the realm of pet couture, a bespoke pet sweatshirt emerges as an exceptional statement steeped...

PvP Tournaments Flourish Featuring BnS NEO Divine Gems

BNS NEO has recently emerged as one of the most talked-about titles in the online gaming...

How to store Custom Wax paper

Whereas recognizing unequivocal makers can be valuable, focusing in on key thoughts whereas...

Comprehensive Guide to Impact Test Equipment

Impact Test Equipment is a critical tool in the field of material science and engineering, used...

Understanding Your Rights as a Taxi Driver in the UK

Navigating the world of taxi licensing in the UK can be complex and challenging. For taxi...