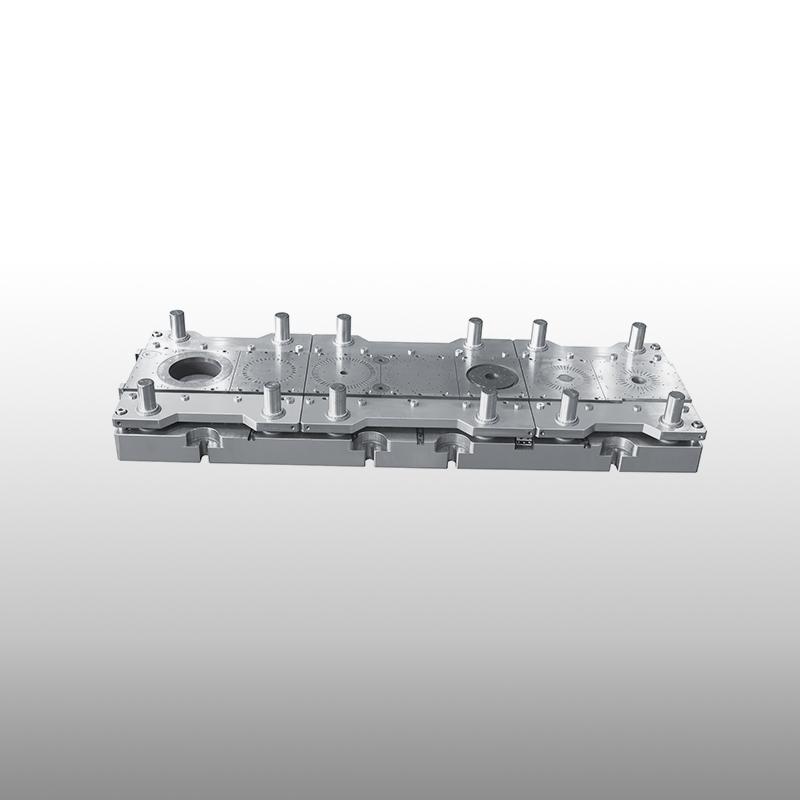

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posted 2025-01-15 07:40:32

0

119

Cerca

Categorie

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leggi tutto

Comprehensive Insights into Medical Test Equipment

Medical Test Equipment: A Pivotal ToMedical Test Equipmentng>The field of medical test...

The Essential Guide to Flame Test Equipment

The Flame Test Equipment, a cornerstone of analytical chemistry, stands as a testament to human...

Electric Wheelchair Market Statistical Symphony: Segmentation, Outlook, and Overview in Market Trends | 2024-2030

Anticipated Growth in Revenue:

The Electric Wheelchair Market was valued at USD 7.92...

Consumer Identity and Access Management (CIAM) Market Overview, Leading Providers, and Forecast till 2032

Polaris Market Research announces the release of its latest research study on Consumer...

The Essential Role of Automotive Rubber Oil Seals

Introduction

Overview of automotive rubber oil seals and their importance.

Brief mention of...