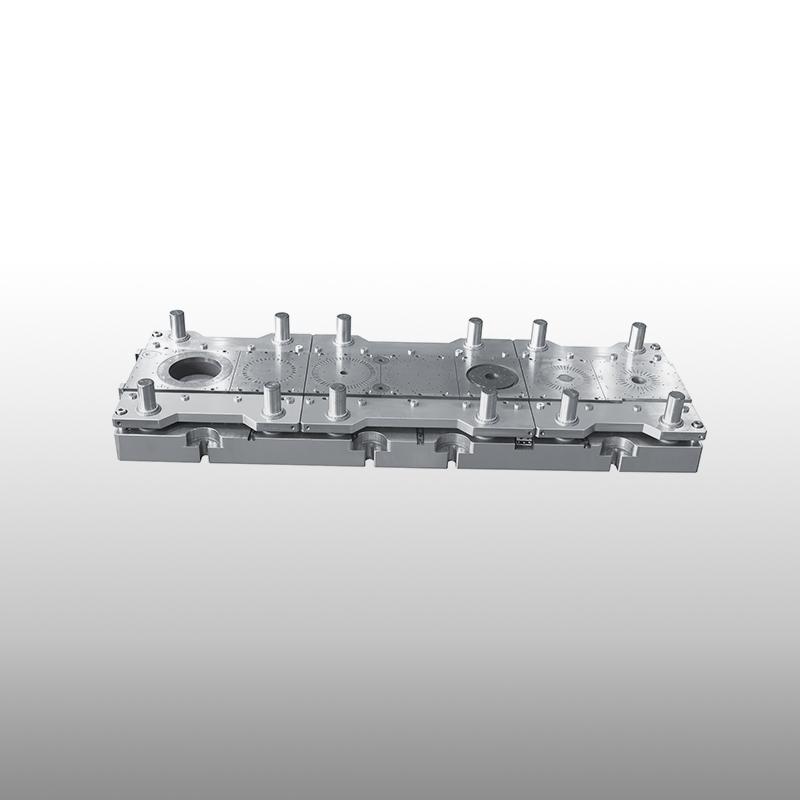

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posted 2025-01-15 07:40:32

0

208

Search

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Professional Data Center Re-Engineering Support and Consulting in India | IT Optimization

For businesses in India seeking to optimize their data center infrastructure, professional...

Experience the Thrill of Panoramic Padel Tennis Courts by Jiu Ruo Oneness Sports Goods

Padel tennis has quickly become one of the most exhilarating and rapidly growing sports in recent...

Pokémon TCG Pocket Meta-Decks – Tier-Liste 2024

Meta-Decks Übersicht

Möchtet ihr wissen, welche Decks im Pokémon TCG Pocket...

Strategic Analysis of the Sauces Industry: Growth Opportunities and Trends to 2030

A newly compiled market analysis indicates that the Sauces Industry, valued at USD...

Essential Aspects of Test Equipment

The realm of Test Equipment is a cornerstone of quality assurance and technological advancement...