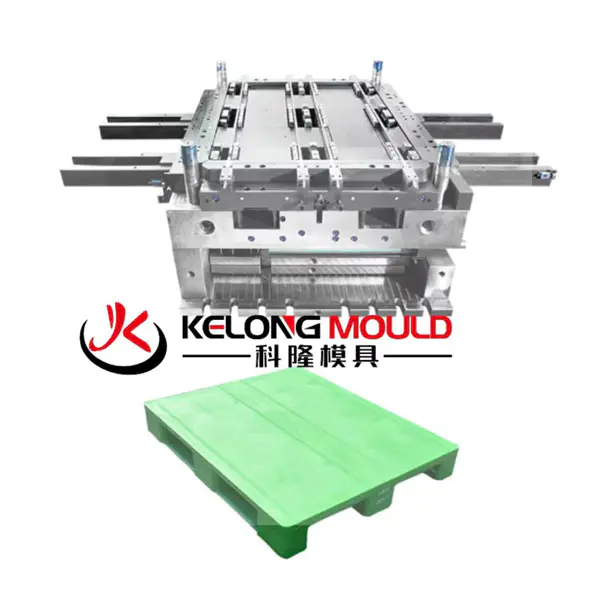

Plastic pallet moulds are essential tools in the manufacturing of plastic pallets, but they are not immune to problems. Common issues such as wear and tear, nozzle blockages, cooling system failures, dimensional inaccuracies, surface defects, and ejection problems can all affect the efficiency and quality of production. By implementing regular maintenance schedules, using high-quality materials, and investing in advanced mould designs and technologies, manufacturers can minimize these issues and extend the lifespan of their plastic pallet moulds. This proactive approach ensures smoother production cycles, better quality products, and reduced downtime, ultimately causing more cost-effective operations.

Căutare

Categorii

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Citeste mai mult

ラブドールMissdoll紹介

今日は人気ブランド、Missdollを紹介したいと思います。このブランドのメーカーは、とても高い技術力を持っていて、最新の材質や機能を堪能しています。更に、高いコストをかかって、とてもいい品質の...

MMOexp Fans express disappointment over the missing classic mode in Call of Duty: Black Ops 6 Season 2 Reloaded

The CoD Black Ops 6 Bot Lobbies community is buzzing with frustration after the highly...

The Power and Precision of Heavy Duty Reciprocating Saws

A heavy-duty reciprocating saw is designed for demanding applications, providing exceptional...

Best Overseas Education Consultant: Your Guide to Studying Abroad

Studying abroad is a dream for many students seeking world-class education, better career...

IEC62368 Test Equipment: Essential Needs and Applications

The term IEC62368 Test Equipment refers to a range of tools and devices designed to ensure...