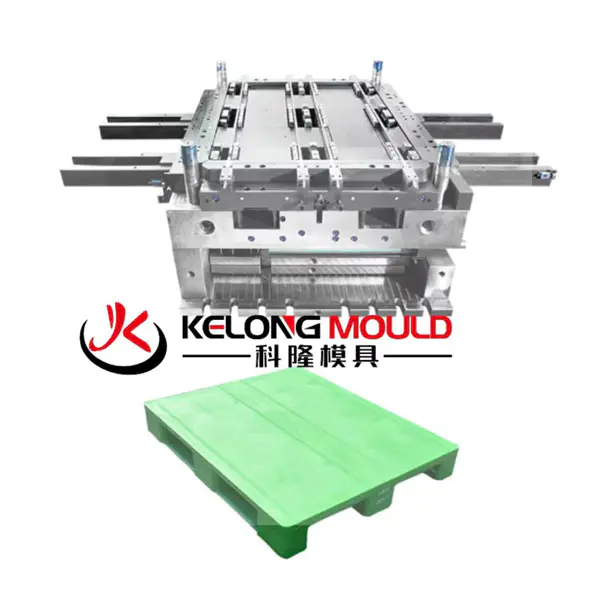

Plastic pallet moulds are essential tools in the manufacturing of plastic pallets, but they are not immune to problems. Common issues such as wear and tear, nozzle blockages, cooling system failures, dimensional inaccuracies, surface defects, and ejection problems can all affect the efficiency and quality of production. By implementing regular maintenance schedules, using high-quality materials, and investing in advanced mould designs and technologies, manufacturers can minimize these issues and extend the lifespan of their plastic pallet moulds. This proactive approach ensures smoother production cycles, better quality products, and reduced downtime, ultimately causing more cost-effective operations.

- FAVORITEN

- NEUIGKEITEN

- EXPLORE

- Seiten

- Gruppen

- Veranstaltungen

- Blogs

- Marktplatz

- Angebote

- Jobs

- Foren

- Filme

- Spiele

Search

Nach Verein filtern

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Choosing the Right Website Design Company in Kerala: A Comprehensive Guide

In today’s digital age, a website serves as the face of a business. It is the first point...

Effect of Phase Ratio Control on Mechanical Properties of Duplex Stainless Steel Pipe

Duplex stainless steel is a special stainless steel material in which ferrite phase (α...

What ingredients are in SlimSure?

Unlock a Healthier, Fitter You with SlimSure Weight Loss Supplement

In today's fast-paced world,...

Curb Stone Mould China

Curb Stone Mould China WELCOME TO SELECT FUJIAN SELECT EQUIPMENT MANUFACTURING CO.,LTD. Located...

How Does Implementing Web Guiding System Revolutionize The Manufacturing Process in the Packaging Industry

Maintaining precise control over web materials is essential in the packaging industry to ensure...