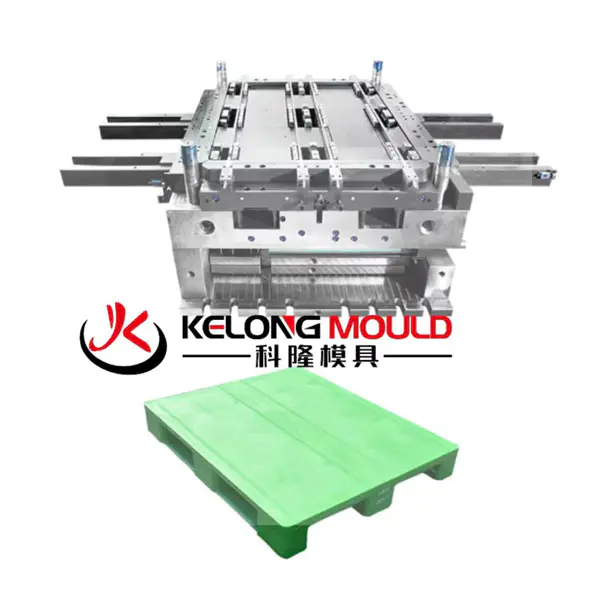

Plastic pallet moulds are essential tools in the manufacturing of plastic pallets, but they are not immune to problems. Common issues such as wear and tear, nozzle blockages, cooling system failures, dimensional inaccuracies, surface defects, and ejection problems can all affect the efficiency and quality of production. By implementing regular maintenance schedules, using high-quality materials, and investing in advanced mould designs and technologies, manufacturers can minimize these issues and extend the lifespan of their plastic pallet moulds. This proactive approach ensures smoother production cycles, better quality products, and reduced downtime, ultimately causing more cost-effective operations.

Zoeken

Categorieën

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

An Inside Look at How Motorized Skateboards Work

Have you ever considered the impact of [keyword] on our daily lives skateboard motorized....

Comprehensive Guide to Cable Testing Equipment

Cable Testing Equipment is a crucial tool in the field of electrical and telecommunications...

and they're versatile enough to be worn Dior in different ways

Aron only wears her large sweatshirt with a long floral number. This idea of subsuming arises in...

Solar Pump Factory becomes a cornerstone of sustainable energy solutions worldwide

Over the years, solar pump technology has undergone significant advancements. Early models were...

How to Choose the Right Industrial Mould Manufacturer for Your Business Needs?

Selecting the right industrial moulds manufacturer requires careful consideration of several...