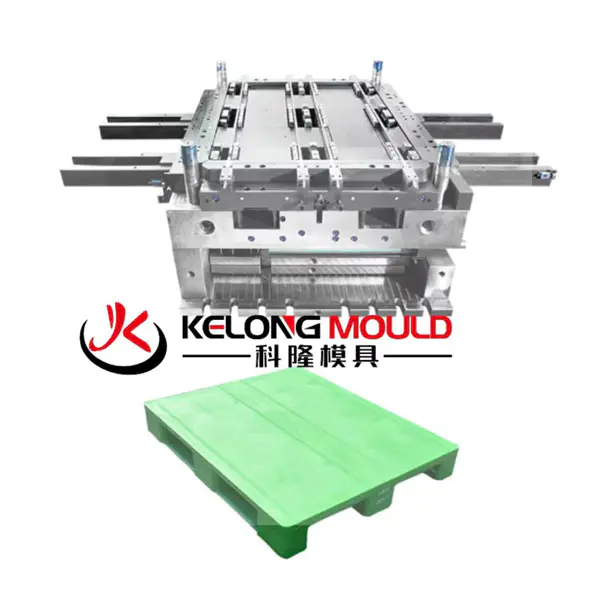

Plastic pallet moulds are essential tools in the manufacturing of plastic pallets, but they are not immune to problems. Common issues such as wear and tear, nozzle blockages, cooling system failures, dimensional inaccuracies, surface defects, and ejection problems can all affect the efficiency and quality of production. By implementing regular maintenance schedules, using high-quality materials, and investing in advanced mould designs and technologies, manufacturers can minimize these issues and extend the lifespan of their plastic pallet moulds. This proactive approach ensures smoother production cycles, better quality products, and reduced downtime, ultimately causing more cost-effective operations.

Search

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Enterprise Robotic Process Automation Market Size, Share, Growth | Global Report [2024-2032]

Enterprise Robotic Process Automation Market: A Comprehensive Analysis

The Enterprise Robotic...

Can Probiotics Help with Thrush?

Thrush is a frustrating and often stubborn health issue that can occur when the body’s...

How to Identify Instagrammers with TikTok Influence and Collaborate Effectively

How to Find TikTok Influencer In today's digital age, social media platforms have become a...

Best Forex Trading Platforms India

Forex trading in India is regulated by the Reserve Bank of India...

Why Every Electronics Workspace Needs an ESD Mat

ESD anti-static table mats are essential in environments where electronic components are handled....