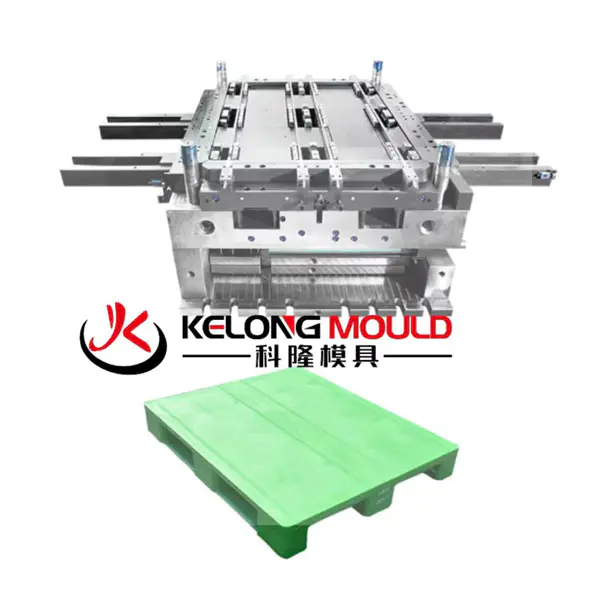

Plastic pallet moulds are essential tools in the manufacturing of plastic pallets, but they are not immune to problems. Common issues such as wear and tear, nozzle blockages, cooling system failures, dimensional inaccuracies, surface defects, and ejection problems can all affect the efficiency and quality of production. By implementing regular maintenance schedules, using high-quality materials, and investing in advanced mould designs and technologies, manufacturers can minimize these issues and extend the lifespan of their plastic pallet moulds. This proactive approach ensures smoother production cycles, better quality products, and reduced downtime, ultimately causing more cost-effective operations.

Rechercher

Catégories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Essential Guide to Plug Socket Tester

A Plug Socket Tester is an essential tool for anyone who deals with electrical systems. Whether...

Best MBBS Abroad Consultancy: Your Gateway to a Successful Medical Career

Choosing the right consultancy is crucial for students aspiring to pursue an MBBS degree abroad....

Comprehensive Electric Motor Testing System: Key Aspects and Requirements

The Electric Motor Testing System is a crucial component in the field of electrical engineering,...

Does the cabinet dehumidifier support setting target humidity and automatic adjustment?

Cabinet dehumidifiers generally support setting target humidity and automatically adjusting...

Ferrite Magnets Applications

Wholesale Ferrite magnet

Speaker Systems

-Consumer-Level Speakers: Ferrite magnets are used in...