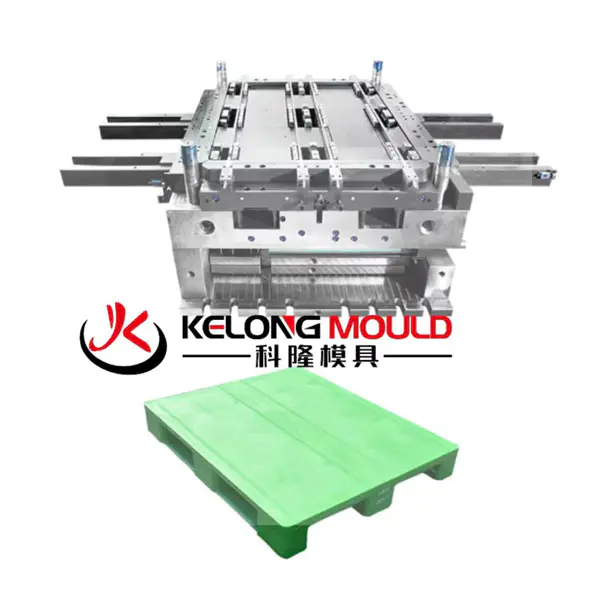

Plastic pallet moulds are essential tools in the manufacturing of plastic pallets, but they are not immune to problems. Common issues such as wear and tear, nozzle blockages, cooling system failures, dimensional inaccuracies, surface defects, and ejection problems can all affect the efficiency and quality of production. By implementing regular maintenance schedules, using high-quality materials, and investing in advanced mould designs and technologies, manufacturers can minimize these issues and extend the lifespan of their plastic pallet moulds. This proactive approach ensures smoother production cycles, better quality products, and reduced downtime, ultimately causing more cost-effective operations.

Search

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Teen Patti Go APK

Introducing the Teen Patti Go APK

Teen Patti Go APK has rapidly gained a dedicated user...

강원랜드, 제2카지노 영업장 본격 조성

강원랜드, 제2카지노 영업장 본격 조성

강원랜드가 1796억 원을 투자해 제2카지노 영업장을 조성합니다. 이번 프로젝트는 2027년 12월...

The Rise of Gingham Dog Harnesses: A Fashion Statement for Furry Friends

Gingham fabric dates back to the 17th century, originally made from cotton and known for its...

El Gouna: The Red Sea’s Hidden Gem for Spa and Relaxation

Nestled along the Red Sea coast of Egypt, El Gouna is a tranquil, luxurious resort town that...

How to Style a Men's T-Shirt for Any Occasion

What do you know about mens t-shirts.

Men's t-shirts are a staple in any wardrobe, but they don't...