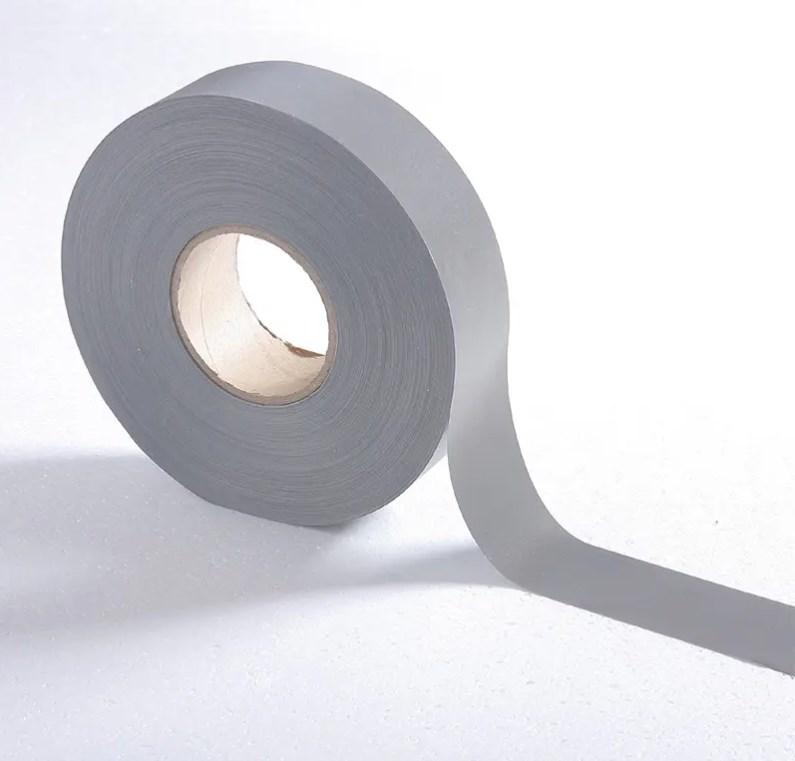

Reflective material plays a pivotal role in enhancing visibility and safety across various industries and applications. With its unique properties, it significantly improves visibility in low-light conditions, contributing to the safety of individuals and vehicles alike.

Reflective material possesses several key properties that make it indispensable for safety applications. Firstly, it exhibits high retroreflectivity, meaning it efficiently redirects light back to its source. This property allows reflective material to stand out even in darkness, making it invaluable for nighttime visibility. Additionally, reflective material is durable and weather-resistant, ensuring its effectiveness in various environmental conditions.

In low-light conditions, such as dusk or nighttime, reflective material acts as a beacon, significantly enhancing visibility. By reflecting light from headlights, street lamps, or other light sources, it creates conspicuous markers on objects, making them easily detectable by observers. This visibility enhancement is crucial for pedestrians, cyclists, and motorists, reducing the risk of accidents and improving overall safety.

The manufacturing process of reflective material involves several intricate steps to achieve the desired properties. One common method is the application of microscopic glass beads or prismatic elements onto a substrate, such as fabric or tape. These beads or prisms are precisely distributed to reduce retro-reflectivity. Alternatively, reflective material can be created through the deposition of reflective coatings onto surfaces, employing techniques like vapor deposition or sputtering.

Regardless of the manufacturing method, the goal is to create a surface that efficiently redirects incoming light, thus enhancing visibility. Quality control measures ensure that the reflective material meets stringent safety standards, guaranteeing its effectiveness in real-world applications.

Reflective material finds widespread use across various industries, including transportation, construction, and personal protective equipment. In the transportation sector, reflective tape and markings adorn vehicles, road signs, and safety barriers, improving visibility for drivers and pedestrians alike. In construction, workers wear garments embedded with reflective material to remain visible in hazardous work environments. Similarly, reflective material is integrated into sportswear and outdoor gear to enhance visibility during nighttime activities.

Advancements in reflective material technology continue to drive innovation in safety and visibility. New materials and manufacturing techniques lead to products with enhanced durability, flexibility, and retroreflective properties. Furthermore, research focuses on sustainable materials and manufacturing processes to reduce environmental impact.

In conclusion, reflective material plays a vital role in enhancing visibility and safety in low-light conditions. Its unique properties and versatile applications make it indispensable across various industries. As technology advances, reflective material continues to evolve, promising even greater improvements in visibility and safety for years to come.