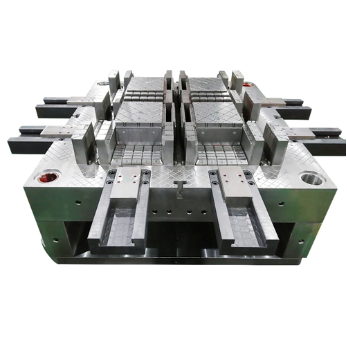

In the intricate world of global trade and logistics, the Export and Shipping Pallet Mould emerges as a vital tool for businesses involved in exporting and shipping goods across borders. From a customer's standpoint, the efficiency, reliability, and practicality of this mould play a crucial role in ensuring the smooth flow of products through the intricate web of international supply chains. In this exploration, we delve into the customer-centric aspects of the Export and Shipping Pallet Mould, highlighting its contribution to meeting the demands of global trade and optimizing the export and shipping processes.

Understanding Customer Needs: Core Features of Export and Shipping Pallet Mould

International Standard Compliance:

Customers in the export and shipping industry prioritize compliance with international standards. The Export and Shipping Pallet Mould is designed to meet or exceed established norms, ensuring that the pallets produced adhere to recognized specifications and quality benchmarks set by global trade regulations.

Robust Construction for Long-Distance Transport:

The mould's robust construction is a fundamental feature valued by customers involved in long-distance shipping. Pallets created with this mould are engineered to withstand the rigors of international transportation, ensuring that goods arrive at their destination in optimal condition.

Optimized Dimensions for Containerization:

Efficiency in containerization is crucial for cost-effective shipping. Customers appreciate the Export and Shipping Pallet Mould for its ability to produce pallets with dimensions optimized for fitting seamlessly into standard shipping containers, maximizing cargo capacity and minimizing wasted space.

Compatibility with Automated Handling Systems:

With the increasing automation of logistics processes, compatibility with automated handling systems is a key consideration for customers. The Export and Shipping Pallet Mould is designed to create pallets that seamlessly integrate into automated warehouses and loading/unloading systems, enhancing overall operational efficiency.

Adaptability to Different Materials:

Recognizing the diversity of goods being shipped, the mould is engineered to be adaptable to different materials. This flexibility allows customers to choose materials based on the specific characteristics of their products, ensuring optimal protection during transit.

Customization Options for Varied Products:

Every industry has unique products with distinct shipping requirements. The Export and Shipping Pallet Mould offers customization options, allowing customers to tailor pallets according to the specific needs of their goods, whether fragile, heavy, or irregularly shaped.

Durability for Multiple Use Cycles:

Sustainability in logistics is a growing concern, and customers appreciate the durability of the Export and Shipping Pallet Mould. The pallets it produces are designed for multiple use cycles, reducing the need for frequent replacements and contributing to a more sustainable shipping process.

Ease of Handling and Stacking:

Efficient handling and stacking of pallets are critical aspects for both shippers and receivers. The Export and Shipping Pallet Mould is optimized for ease of handling and stacking, facilitating smooth operations in warehouses, distribution centers, and during transportation.

Applications and Practical Utility:

The Export and Shipping Pallet Mould finds applications across a spectrum of industries engaged in global trade, contributing to the efficient and secure movement of goods.

Manufacturing and Export of Goods:

Manufacturers benefit from the mould's ability to create pallets tailored for the international shipping of products. The optimized dimensions and durability of the pallets ensure that goods reach global destinations in pristine condition.

Retail and E-commerce Export:

In the era of global e-commerce, the Export and Shipping Pallet Mould aids in creating pallets suitable for the export of goods to customers worldwide. The standardized dimensions enhance compatibility with various shipping carriers and modes of transport.

Automotive Component Export:

The automotive industry relies on precise shipping of components to assembly plants worldwide. The mould's ability to produce pallets customized for automotive components ensures secure and organized transportation, minimizing the risk of damage.

Pharmaceutical and Medical Equipment Export:

The export of pharmaceuticals and medical equipment demands strict adherence to international standards. The Export and Shipping Pallet Mould contributes to creating pallets that meet regulatory requirements and safeguard the integrity of sensitive products during transit.

Food and Beverage Exports:

Perishable goods require special consideration during shipping. The mould allows for the creation of pallets suited for the export of food and beverages, ensuring proper ventilation and protection to maintain product quality.

Design Challenges and Solutions:

Designing the Export and Shipping Pallet Mould involves addressing specific challenges to meet the demands of global trade and ensure customer satisfaction.

Standardization vs. Customization:

Balancing standardization with the need for customization is a challenge in mould design. Designers work to create moulds that offer standardized dimensions for efficiency while allowing for customization options to meet diverse product requirements.

Optimizing Weight and Strength:

Achieving the optimal balance between weight and strength is crucial. Designers focus on selecting materials and structural configurations that provide the necessary strength for long-distance shipping while keeping pallet weight within acceptable limits for cost-effective transportation.

Compatibility with Automated Systems:

Ensuring compatibility with automated handling systems requires precision in design. Designers incorporate features that allow pallets produced by the mould to seamlessly integrate into conveyor systems, robotic arms, and other automated warehouse technologies.

Durability in Harsh Environmental Conditions:

Shipping containers may be exposed to various environmental conditions during transit. Designers address this challenge by selecting materials that withstand temperature variations, humidity, and other factors that could potentially impact pallet durability.

Sustainability Considerations:

Designing for sustainability involves creating pallets with a longer lifespan and considering materials that are eco-friendly. Designers work on optimizing the mould's construction to contribute to sustainable shipping practices.

User Feedback and Satisfaction:

User feedback provides valuable insights into the real-world performance of the Export and Shipping Pallet Mould.

Global Compatibility:

Users appreciate the global compatibility of the mould, noting that the pallets it produces are well-received by international shipping carriers and conform to the varying standards of different countries.

Durability in Transit:

Positive feedback revolves around the durability of pallets during long-distance transit. Users report that the pallets withstand the challenges of international shipping, protecting goods from damage and ensuring they arrive in excellent condition.

Efficiency in Warehousing:

Warehousing efficiency is a crucial consideration for users. The mould's contribution to creating pallets optimized for automated handling systems receives positive feedback, streamlining operations in modern warehouses.

Customization for Diverse Products:

Users appreciate the customization options provided by the Export and Shipping Pallet Mould. This flexibility allows businesses to address the specific needs of different products, ensuring secure and efficient transportation.

Sustainability Practices:

Sustainability is a growing concern, and users acknowledge the mould's contribution to sustainable shipping practices through the creation of durable pallets that can withstand multiple use cycles.

Conclusion:

In conclusion, the Export and Shipping Pallet Mould, viewed from a customer's perspective, stands as an indispensable tool for businesses engaged in the complexities of global trade. Its core features, including compliance with international standards, optimized dimensions, compatibility with automated handling systems, and durability for long-distance transport, align with the diverse needs of industries ranging from manufacturing to retail and pharmaceuticals. Designers play a pivotal role in overcoming challenges and continuously refining the mould's functionalities to meet and exceed customer expectations. As global trade continues to evolve, the Export and Shipping Pallet Mould remains a crucial asset, contributing to the seamless movement of goods across borders and facilitating the efficiency of international supply chains.