In modern industrial manufacturing, Titanium Magnesium Alloy Profile, as an important raw material, is increasingly favored in various fields due to its excellent performance and wide application prospects. This article will conduct an in-depth analysis of the advantages, production process and main application fields of the industrial Profile Titanium Magnesium Alloy Profile, providing you with comprehensive knowledge and insights.

I. What is the industrial Profile Titanium Magnesium Alloy Profile?

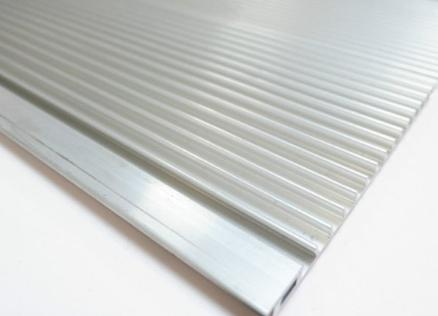

Industrial Profile Titanium Magnesium Alloy Profile refers to the shape change of aluminum alloy materials through extrusion or other processing techniques to form aluminum products with specific cross-sections and mechanical properties. These Titanium Magnesium Alloy profiles are usually widely used in industries such as construction, automobiles, machinery, electronics, aerospace, etc.

Ii. Advantages of the Titanium Magnesium Alloy Profile

1. Lightweight: The density of aluminium is relatively low, only about one-third that of steel. This makes the Titanium Magnesium Alloy Profile an ideal choice for lightweighting industrial products, especially in the fields of aviation and automobiles, which can significantly improve fuel efficiency.

2. Corrosion resistance: The surface of aluminum materials is prone to form an oxide film, which has excellent corrosion resistance and can effectively prevent environmental factors from eroding the material. It is especially suitable for use in damp or chemically corrosive environments.

3. Excellent electrical and thermal conductivity: Aluminum has excellent electrical and thermal conductivity, making it highly suitable for the manufacturing of electrical and heat exchange equipment.

4. Processing flexibility: The extrusion process of the Titanium Magnesium Alloy Profile allows for the manufacture of various complex cross-sectional shapes to meet the requirements of different applications. Meanwhile, aluminium is easy to cut, weld and assemble, which brings convenience to subsequent production.

5. Recyclability: The recycling rate of Titanium Magnesium Alloy Profile is extremely high, and its performance remains unchanged after recycling, which is in line with the sustainable development concept of green environmental protection.

6. Aesthetics: The surface treatment methods of Titanium Magnesium Alloy Profile are diverse, such as anodizing, spraying, polishing, etc., which can meet the appearance requirements of different users.

Iii. The production process of Titanium Magnesium Alloy Profile

The production process of Titanium Magnesium Alloy Profile mainly includes the following steps:

1. Raw material preparation: Select high-quality aluminum alloy materials, usually alloys of aluminum and other metal elements, to enhance the material's performance.

2. Melting and casting: Melting aluminum alloy raw materials at high temperatures to produce aluminum ingots.

3. Extrusion molding: Pour the molten aluminum into the extruder and use pressure to extrude the aluminum through the die to form the shape. This process requires precise control of temperature and pressure to ensure the density and strength of the Titanium Magnesium Alloy Profile.

4. Cooling and Cutting: After the extruded Titanium Magnesium Alloy profiles are cooled, they are cut to a fixed length to ensure that each Titanium Magnesium Alloy Profile conforms to the design specifications.

5. Surface treatment: According to customer requirements, surface treatments such as anodizing, electrophoretic coating, and spraying are carried out to enhance the corrosion resistance and appearance of the Titanium Magnesium Alloy Profile.

6. Quality Inspection: Each batch of Titanium Magnesium Alloy Profile is inspected, including tensile strength, surface quality and dimensional tolerance, etc., to ensure that it complies with national standards.

Iv. Main Application Fields of Titanium Magnesium Alloy Profile

Titanium Magnesium Alloy Profile has been widely used in multiple industries due to its unique advantages:

1. Construction industry: Titanium Magnesium Alloy Profile is widely used in the construction industry, for example, in window frames, curtain walls, sunrooms, doors, etc. Its lightweight and corrosion-resistant characteristics make the appearance of buildings more beautiful and also extend the service life of buildings.

2. Transportation: In the manufacturing of transportation means such as automobiles, trains, ships and aircraft, Titanium Magnesium Alloy Profile is used in parts such as body structures, brackets and decorative parts, which can not only reduce self-weight but also ensure structural strength.

3. Machinery and equipment: Industrial automation equipment and mechanical fixtures usually adopt Titanium Magnesium Alloy Profile. Its high strength, light weight and easy processing characteristics make the movement of the equipment more flexible and reduce the energy consumption of the equipment.

4. Electronics and Electrical Engineering: Titanium Magnesium Alloy Profile is widely used in fields such as heat dissipation and enclosures of electronic products. Its excellent thermal conductivity helps electronic devices dissipate heat effectively and extends the working life of the system.

5. Aerospace: In the aerospace field, the Titanium Magnesium Alloy Profile is widely used in parts such as the fuselage structure and wing beams. Its characteristics of high strength and low weight are important components of aircraft design.

6. Furniture Manufacturing: In modern home design, Titanium Magnesium Alloy Profile is widely used in the manufacturing of furniture such as tables, chairs, bookshelves and display cases, providing a more modern and simple appearance.

V. Future Development Trends of the Industry

With the continuous advancement of technology and the enhancement of environmental awareness, the future development trends of the Titanium Magnesium Alloy Profile industry are mainly reflected in the following aspects:

1. Intelligent production: With the development of automation and digital technologies, the production equipment of Titanium Magnesium Alloy Profile will tend to be intelligent, improving production efficiency and product quality.

2. Research and development of new alloys: To meet the demands of higher performance and diverse applications, the research and development of new materials for aluminum alloys is gradually deepening, and new alloy formulas will emerge.

3. Application of Environmental protection technology: During the production and processing of Titanium Magnesium Alloy Profile, more attention will be paid to environmental protection, and more environmentally friendly technologies and materials will be developed.

4. International market Expansion: The global demand for Titanium Magnesium Alloy Profile is constantly rising. Chinese Titanium Magnesium Alloy Profile enterprises will further explore the international market and enhance their competitiveness.

Vi. Conclusion

The industrial Profile Titanium Magnesium Alloy Profile has been widely used in many industries such as construction, transportation, machinery and electronics due to its many advantages such as lightweight, corrosion resistance, good electrical conductivity and thermal conductivity. With the advancement of technology and the changes in market demand, the Titanium Magnesium Alloy Profile industry will also embrace a broader development prospect.

In the future development, the Titanium Magnesium Alloy Profile should not only meet the demands of industrial production, but also continuously exert efforts in aspects such as environmental protection, economy and efficiency. We look forward to the Titanium Magnesium Alloy Profile industry bringing more convenience and innovation to our lives.

Titanium Magnesium Alloy Profile https://www.rongxinhao.com/titanium-magnesium-alloy-profile.html