Woven polypropylene bags are widely used in various industries due to their versatility and durability. These bags are made from polypropylene fibers woven together, creating a fabric that balances strength and flexibility. This makes them suitable for packaging a range of goods, from agricultural products to industrial materials.

One of the key advantages of woven polypropylene bags is their resistance to tearing and punctures. This property allows them to protect contents effectively during transportation and storage. Additionally, the bags exhibit good resistance to moisture, which helps preserve products sensitive to humidity, such as grains, seeds, and fertilizers.

The lightweight nature of woven polypropylene bags contributes to reduced shipping costs. Despite being light, they maintain a robust structure, ensuring that items remain secure. This combination of strength and low weight has made these bags a preferred choice for bulk packaging needs.

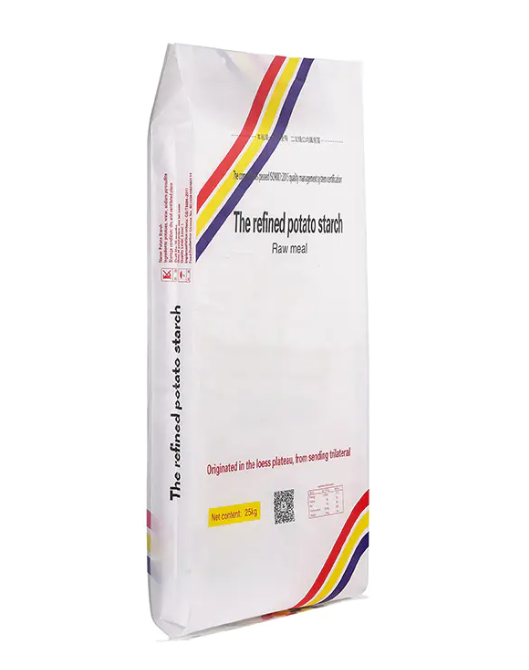

Another important feature is the ability to customize woven polypropylene bags. They can be manufactured in various sizes and with different printing options, allowing businesses to include branding or important product information directly on the bag. This customization supports marketing efforts while also making identification easier in storage and handling.

Environmental considerations are increasingly influencing packaging choices. Woven polypropylene bags are recyclable and can be reused multiple times, which helps reduce waste compared to single-use plastic alternatives. Their durability also means fewer replacements, contributing to resource savings over time.

In addition to packaging, woven polypropylene bags have found applications in construction and gardening. For instance, they can be used for sandbags in flood control or for carrying soil and compost. Their sturdy weave enables them to hold heavy materials without breaking, providing practical support in various settings.

Woven polypropylene bags combine practical benefits such as durability, moisture resistance, and customization options. Their use in multiple sectors highlights their adaptability, making them a valuable component in packaging and material handling solutions.