Tracked machinery, such as excavators, bulldozers, and loaders, is the backbone of industries like construction and mining, relying on advanced components to deliver power and precision. Bosch Rexroth hydraulic parts, alongside Isuzu engine components, Kawasaki hydraulics, and Hitachi hydraulics, are essential for ensuring these machines operate effectively in demanding environments. This article explores the role of Bosch Rexroth hydraulic parts and their contribution to tracked machinery performance.

Bosch Rexroth Hydraulic Parts: Engineering Excellence

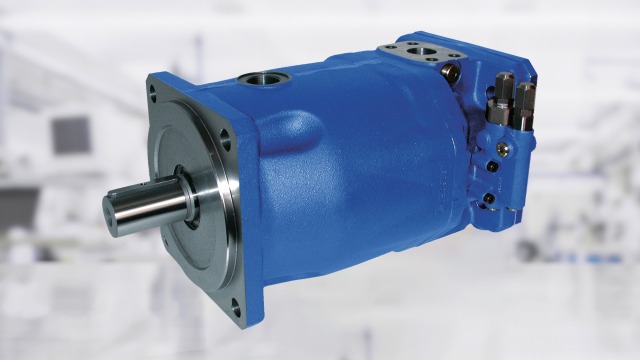

Bosch Rexroth is a leader in hydraulic technology, providing components that drive the movement and control systems of tracked machinery. Their parts, including axial piston pumps, motors, and valves, are used in equipment from brands like Caterpillar, Komatsu, and John Deere. For example, the Bosch Rexroth A10V pump and A4VG motor are designed for high efficiency and durability, enabling precise control and powerful performance in excavators and bulldozers. These components are critical for maintaining smooth operation under heavy loads.

Key Attributes of Bosch Rexroth Parts

-

Precision Design: Engineered for accuracy, Bosch Rexroth hydraulics ensure consistent performance in complex tasks.

-

Robustness: Built to withstand extreme pressures and harsh conditions, these parts support long-term reliability.

-

Versatility: Compatible with a wide range of tracked machinery, from compact excavators to large-scale mining equipment.

Complementary Components: Isuzu, Kawasaki, and Hitachi

While Bosch Rexroth hydraulics provide the muscle for tracked machinery, other components play vital roles. Isuzu engines, known for their durability, power equipment with parts like fuel injectors and turbochargers, such as the 6HK1 fuel pump (part no. 898009-3971). Kawasaki hydraulics, including K3V pumps, and Hitachi hydraulics, like swing motors, complement Bosch Rexroth by enhancing system performance. Together, these components ensure machinery delivers both power and precision.

Importance of Component Availability

Reliable access to hydraulic and engine parts is crucial for minimizing downtime in tracked machinery. Bosch Rexroth hydraulic parts, along with Isuzu, Kawasaki, and Hitachi components, are sourced globally, offering both OEM and aftermarket options. Remanufactured parts, restored to original specifications, provide a sustainable alternative, reducing environmental impact while maintaining performance standards for heavy equipment.

Meeting the Challenges of Tracked Machinery

Tracked machinery operates in tough conditions, from dusty quarries to frozen job sites. Bosch Rexroth hydraulic parts deliver the control and strength needed for tasks like digging and lifting, while Isuzu engines and Kawasaki and Hitachi hydraulics contribute to overall system reliability. These components work in harmony to ensure equipment performs efficiently, supporting critical industrial operations.

Looking Forward

The demand for high-quality hydraulic components like those from Bosch Rexroth Hydraulic parts remains strong as tracked machinery continues to drive progress in construction and mining. By ensuring the availability of these precision-engineered parts, operators can maintain equipment performance, meeting the rigorous demands of modern industrial projects.