Ultra-narrow linewidth fiber lasers are critical for applications such as coherent optical communications, high-precision metrology, and quantum optics. Achieving and maintaining their exceptional spectral purity requires careful attention to thermal and mechanical stability. Even minor environmental disturbances can degrade performance, making robust design essential.

Thermal Stability Challenges

Temperature fluctuations induce refractive index changes in optical fibers, leading to phase noise and linewidth broadening. To mitigate this:

Thermal Isolation: Fiber lasers should be housed in temperature-stabilized enclosures or actively cooled to minimize drift.

Low Thermal Expansion Materials: Components like fiber Bragg gratings (FBGs) and laser cavities benefit from materials with low coefficients of thermal expansion (CTE), such as Invar or carbon composites.

Active Temperature Control: Thermoelectric coolers (TECs) and PID loops maintain a constant operating temperature, reducing thermal-induced frequency jitter.

Mechanical Stability Considerations

Vibrations and acoustic noise can perturb the laser cavity, causing phase instabilities. Key strategies include:

Vibration Isolation: Optical tables, passive dampers, or active vibration cancellation systems help suppress external mechanical noise.

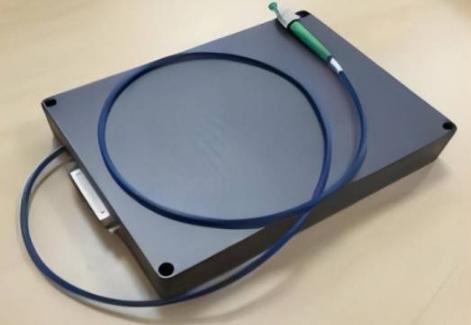

Rigid Packaging: Fiber coils and components should be securely mounted to minimize microphonic effects. Strain relief techniques prevent tension-induced birefringence.

Acoustic Shielding: Enclosures with sound-absorbing materials reduce sensitivity to ambient noise.

Integration of Thermal and Mechanical Stability

A holistic approach combines both thermal and mechanical stabilization:

Monolithic Designs: Reducing splice points and free-space optics minimizes susceptibility to environmental changes.

Feedback Systems: Pound-Drever-Hall (PDH) locking or electronic feedback loops compensate for residual instabilities.

Hermetic Sealing: Protecting the laser from humidity and air currents enhances long-term reliability.

Conclusion

Ultra-narrow linewidth fiber lasers demand meticulous thermal and mechanical management to maintain their performance. Advances in material science, active stabilization, and vibration damping continue to push the boundaries of coherence and stability, enabling next-generation photonic systems.

By addressing these challenges, engineers can ensure that ultra-narrow linewidth lasers meet the stringent demands of cutting-edge optical technologies.