Tapered Drilling Tools are essential equipment in various industries, particularly in drilling applications where precise control and maneuverability are crucial. These tools feature a gradually decreasing diameter from the base to the tip, a design that provides several advantages in drilling processes.

One of the main uses of tapered drilling tools is in applications that require drilling into hard-to-reach or confined spaces. For example, in the construction of wells or geothermal systems, tapered drill bits allow operators to drill through tough materials while maintaining the accuracy of the drill trajectory. The design helps to prevent excessive wear on the drill, which can occur when using standard bits in these challenging environments.

Another significant benefit of tapered drilling tools is their ability to facilitate a smooth transition between different types of materials. Whether drilling through soft soil or harder rock formations, the taper design can minimize the risk of tool jamming, providing a more consistent performance throughout the drilling process.

These tools are also integral in the mining and oil industries, where drilling efficiency and precision are essential for resource extraction. The tapered shape allows for more controlled penetration and minimizes the stress on the equipment. Additionally, their versatility enables them to be used with various drilling rigs and machinery.

In summary, tapered drilling tools are crucial for applications that require maneuverability, precision, and durability in challenging drilling conditions. Their gradual taper ensures smoother drilling transitions and extends the lifespan of both the tool and the equipment used.

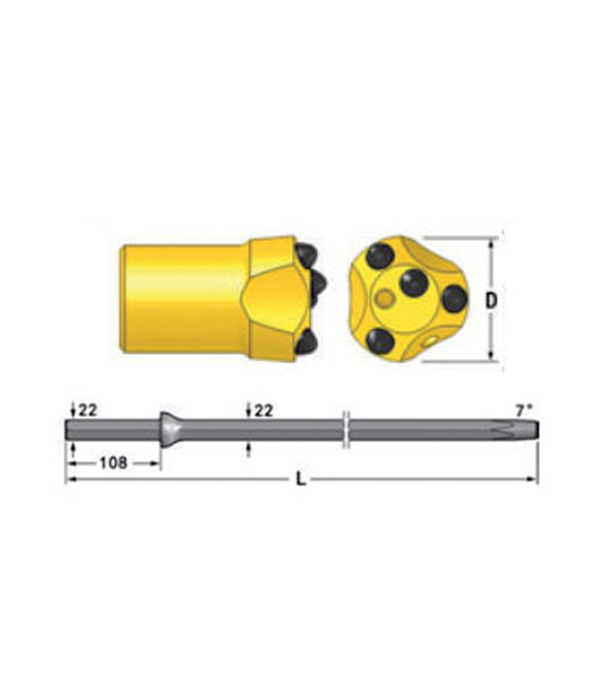

https://www.kqdrill.com/product/tapered-bits/7-degree-tapered-drilling-tools-6.html

1. High fatiue strength and tougness.

2.The crushing ability is strong, the rock drilling speed is fast, and it is convenient for grinding.