Selecting the appropriate Taper Shank Twist Drill is vital for achieving optimal results in any drilling operation. While the design of taper shank drills is versatile, understanding how to match the right drill with the task at hand is crucial for ensuring efficiency and quality in your projects.

When choosing a taper shank twist drill, one of the first factors to consider is the material being drilled. Different materials, such as metal, wood, or plastic, require varying levels of force and cutting power. For instance, tougher metals like stainless steel demand drills made from high-speed steel or carbide, which are more resistant to wear and heat.

Another consideration is the size of the hole required. Taper shank twist drills come in a variety of sizes, and selecting the correct diameter will ensure that the hole is drilled precisely to specifications. It's also important to check the type of taper that corresponds to the machine you will be using. Common tapers include Morse, B16, and BT, and matching the correct taper size will ensure a secure fit.

In addition to size and material compatibility, consider the application. For high-speed operations or where precise measurements are needed, drills with finer flutes or coatings that reduce friction may be a better option. The coating can also provide protection against rust and corrosion, extending the life of the drill.

Ultimately, the choice of taper shank twist drill depends on the specific requirements of your project. By understanding the materials, machine compatibility, and specific application needs, you can select the right tool to achieve efficient and accurate results.

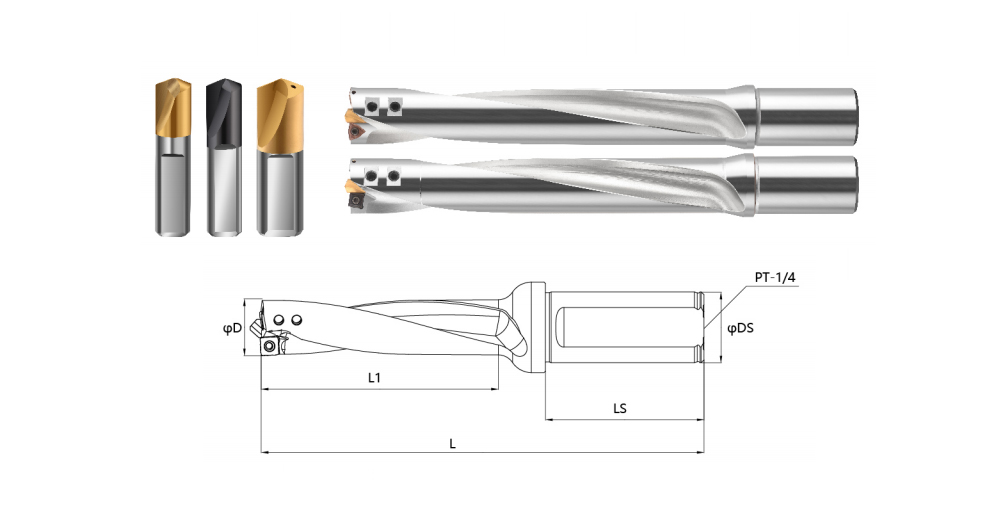

HD-3 8D cutting depth high efficiency self-centering fast drill is a cutting tool designed for efficient machining. It is a fast drill suitable for a depth of cut of 8 diameters (8D), thus enabling efficient machining in deep holes.