Isosorbide, a versatile and sustainable bio-based chemical, is gaining traction in multiple industries, from pharmaceuticals to plastics. The Isosorbide Procurement Intelligence Report offers comprehensive insights into the market, including sourcing strategies, supplier dynamics, price trends, and emerging applications. As a key intermediate for the production of various chemicals, isosorbide is playing a crucial role in driving sustainability across various sectors. This report is essential for businesses seeking to optimize their procurement processes, navigate supply chain complexities, and leverage isosorbide’s growing demand.

What is Isosorbide?

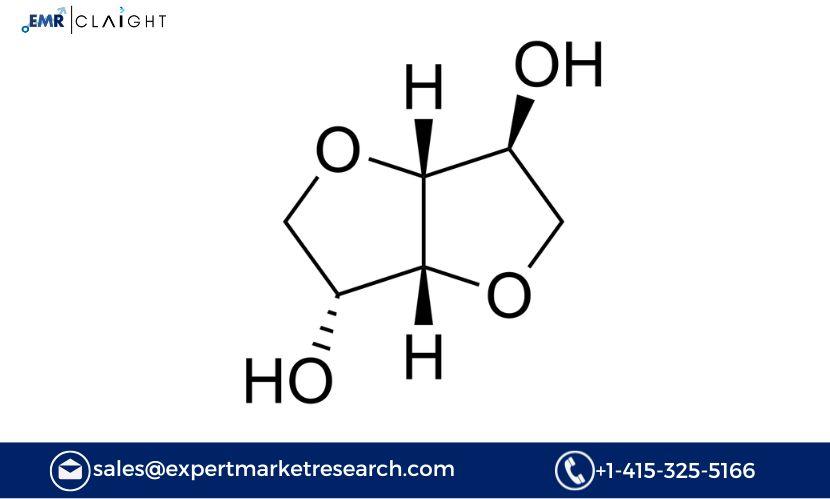

Isosorbide is a renewable chemical derived from the natural sugar sorbitol, which is typically obtained from corn or other plant-based feedstocks. Through a chemical process called dehydration, sorbitol is converted into isosorbide, a colorless, crystalline compound with unique chemical properties. Isosorbide has gained popularity as a building block for producing a wide range of materials, including bio-based plastics, polyesters, and specialty chemicals.

Its exceptional properties, such as high thermal stability, low toxicity, and biodegradability, make it an ideal candidate for various industrial applications. Moreover, isosorbide’s sustainable, bio-based origins have made it a preferred choice in sectors looking to reduce their carbon footprint and shift towards environmentally friendly alternatives to petroleum-based products.

Key Applications of Isosorbide

Isosorbide is a highly versatile chemical that serves a wide variety of applications across multiple industries. Some of the major sectors where isosorbide is used include:

1. Bioplastics and Polymers

One of the most significant applications of isosorbide is in the production of bioplastics and polymers, particularly in the manufacture of polyesters like polybutylene succinate (PBS) and polyethylene terephthalate (PET). These bio-based plastics are gaining popularity as environmentally friendly alternatives to conventional petroleum-based plastics. Isosorbide is often used to replace traditional petrochemical monomers, enabling the creation of biodegradable plastics and reducing dependence on fossil fuels.

2. Pharmaceuticals

In the pharmaceutical industry, isosorbide is primarily used in the production of medications, such as isosorbide dinitrate and isosorbide mononitrate, which are used to treat heart conditions like angina. It is also utilized in the formulation of oral tablets and controlled-release medications due to its ability to regulate the release of drugs in the body.

3. Specialty Chemicals

Isosorbide acts as a precursor in the synthesis of a range of specialty chemicals, including solvents, plasticizers, and surfactants. These chemicals find applications in a variety of sectors, including coatings, adhesives, and lubricants, where they offer benefits such as improved performance and environmental safety compared to their petroleum-based counterparts.

4. Personal Care and Cosmetics

The cosmetic and personal care industry is increasingly turning to isosorbide derivatives for use in products like emulsifiers, moisturizers, and skin-care treatments. These compounds are valued for their ability to improve the stability and texture of cosmetic formulations while maintaining an eco-friendly profile.

5. Food and Beverage

While not as widely used as in other industries, isosorbide has potential applications in the food and beverage sector, where it could be used as a sugar substitute or food additive. However, its use in this sector is still emerging, with research underway to explore its full potential as a functional ingredient.

Get a Free Sample Report with Table of Contents@

Market Trends and Demand Drivers

The global isosorbide market is expected to grow significantly due to several factors driving demand across various industries. The following market trends are particularly noteworthy:

1. Shift Toward Sustainable and Bio-Based Products

As companies and consumers alike push for sustainability, the demand for bio-based chemicals like isosorbide is growing rapidly. The trend toward reducing reliance on fossil fuels and minimizing environmental impact is a key driver for isosorbide’s adoption in bioplastics, packaging materials, and other consumer products.

Additionally, regulations mandating the use of renewable and biodegradable materials in manufacturing are encouraging businesses to explore sustainable alternatives, further boosting demand for isosorbide-derived materials.

2. Innovation in Bioplastics and Eco-Friendly Packaging

The rise in the demand for eco-friendly packaging and bioplastics is another significant trend that is driving the growth of isosorbide. With increasing concerns about plastic waste, especially single-use plastics, many companies are turning to bio-based plastics made from isosorbide as a solution. The use of isosorbide in polyesters offers an attractive alternative to traditional plastics, especially in industries like automotive, consumer goods, and packaging.

3. Technological Advancements in Production Processes

Advances in the production processes for isosorbide are helping to reduce production costs and increase supply. Innovations in catalytic dehydration processes, more efficient enzymatic conversions, and improved biomass feedstocks have made the commercial production of isosorbide more cost-effective. This has the potential to lower the price of isosorbide-based products and expand their use across additional industries.

4. Increasing Use in Pharmaceuticals

Isosorbide’s importance in the pharmaceutical industry continues to rise as the demand for cardiovascular treatments increases. Isosorbide-based drugs like isosorbide dinitrate are critical in the treatment of heart diseases and are expected to see sustained growth in demand, driven by the aging global population and increased incidences of cardiovascular conditions.

5. Supportive Government Policies

Government policies in many regions are encouraging the adoption of renewable chemicals and sustainable materials. This includes tax incentives, subsidies for bio-based products, and regulations pushing industries to adopt more sustainable practices. These policies are expected to further fuel the demand for isosorbide, particularly in the production of bio-based plastics and green chemicals.

Procurement Challenges in Isosorbide Sourcing

While the market for isosorbide is expanding, there are several challenges that businesses face when sourcing this bio-based chemical:

1. Raw Material Availability and Cost Fluctuations

Isosorbide is derived from sorbitol, which is typically produced from corn or other agricultural feedstocks. The price and availability of these raw materials can fluctuate depending on crop yields, weather conditions, and other agricultural factors. These fluctuations can have a significant impact on the cost and reliability of isosorbide procurement.

2. Production Capacity Limitations

The production capacity for isosorbide is still limited compared to traditional petrochemicals. While there has been significant investment in scaling up production, companies may still face challenges in securing large volumes of isosorbide at competitive prices. Supply chain constraints and limited production facilities may lead to supply disruptions, particularly in regions with high demand.

3. Complex Regulatory Environment

The production and use of isosorbide and isosorbide-based products are subject to various regulations, particularly in the pharmaceutical, food, and cosmetic industries. These regulations can vary by region and impact sourcing strategies. Companies must stay informed about compliance requirements to ensure that their procurement processes align with local laws and industry standards.

4. Quality Control and Consistency

Ensuring that isosorbide meets strict quality standards is essential, especially for industries like pharmaceuticals and bioplastics, where product performance is critical. Companies must work with reliable suppliers who can consistently deliver high-quality isosorbide and maintain strict quality control measures.

5. Competition for Supply

As demand for isosorbide rises, companies across different sectors are competing for limited supplies. Businesses must carefully manage their procurement strategies to ensure a consistent supply of isosorbide at competitive prices. Securing long-term contracts and building relationships with reliable suppliers can help mitigate this risk.

Procurement Intelligence in Isosorbide Sourcing

Procurement intelligence can play a crucial role in addressing the challenges associated with isosorbide sourcing. By leveraging data-driven insights, businesses can make more informed procurement decisions, reduce risks, and optimize costs. Here are some ways procurement intelligence can enhance isosorbide sourcing:

1. Market Analysis and Trend Forecasting

Procurement intelligence tools provide businesses with up-to-date market trends, price forecasts, and demand projections, allowing companies to anticipate changes in the market and adapt their sourcing strategies. This helps businesses stay ahead of fluctuations in raw material prices and supply chain disruptions.

2. Supplier Risk Management

By using procurement intelligence, companies can evaluate and monitor suppliers based on key performance indicators such as quality, reliability, and delivery time. This helps businesses mitigate risks and ensure they partner with suppliers who can meet their needs and offer competitive pricing.

3. Cost Optimization

Procurement intelligence tools help businesses identify opportunities to reduce costs by providing insights into market pricing trends, alternative suppliers, and potential negotiation tactics. By streamlining procurement processes, companies can secure the best value for their isosorbide-based products.

4. Supply Chain Visibility

Enhanced visibility into the supply chain allows businesses to track shipments, monitor supplier performance, and identify potential delays. This helps companies ensure a consistent supply of isosorbide and reduce the risk of production disruptions due to supply chain issues.

5. Sustainability and Compliance Monitoring

Procurement intelligence platforms can also help businesses assess the sustainability and regulatory compliance of their suppliers. By tracking sustainability metrics and compliance with environmental standards, companies can ensure that their procurement practices align with industry regulations and their own sustainability goals.

Procurement Strategies for Isosorbide Sourcing

To effectively source isosorbide, businesses should adopt procurement strategies that balance cost, quality, and reliability. Some key strategies include:

1. Diversifying Suppliers

Given the competition for isosorbide and the potential for supply disruptions, businesses should consider diversifying their supplier base. Sourcing isosorbide from multiple suppliers in different regions can help mitigate risks associated with raw material shortages or supply chain disruptions.

2. Long-Term Contracts and Partnerships

Securing long-term contracts with reliable suppliers can provide businesses with stability and more favorable pricing. Building strong relationships with key suppliers can also ensure priority access to isosorbide, especially during periods of high demand.

3. Investing in Sustainability

With the growing importance of sustainability, businesses should prioritize suppliers who offer bio-based, eco-friendly isosorbide products. Investing in sustainable procurement practices not only supports environmental goals but also helps meet consumer demand for green products.

4. Exploring New Production Methods

As production capacity for isosorbide increases, businesses should explore new sources and production methods. This could include partnering with suppliers who are innovating in isosorbide production, such as developing more cost-effective and efficient processes.

5. Leveraging Technology for Procurement Efficiency

Utilizing procurement intelligence platforms can help businesses optimize their procurement processes, reduce costs, and improve supply chain visibility. By adopting technology, companies can streamline their sourcing strategies and stay competitive in the growing isosorbide market.

Related Reports

https://www.expertmarketresearch.com/blogs/top-united-states-atm-services-companies

https://www.expertmarketresearch.com/blogs/top-united-states-smart-thermostat-companies

https://www.expertmarketresearch.com/blogs/top-dog-food-companies