In the steel industry, we often hear the concepts of hot rolling and cold rolling, so what exactly are they?

The rolling of steel profiles is mainly hot rolling, while cold rolling is mainly used to produce small-sized steel profiles and thin plates.

The following are common cold rolling and hot rolling conditions of steel:

Wire: 5.5-40 mm in diameter, coiled, all hot-rolled. After cold drawing, it belongs to cold drawn material.

Round steel: In addition to bright steel with precise dimensions, it is generally hot-rolled, and there are also forged steel (with forging marks on the surface).

Strip steel: both hot-rolled and cold-rolled, and cold-rolled products are generally thinner.

Steel plates: Cold-rolled plates are generally thinner, such as automotive plates; there are more hot-rolled medium-thick plates, some with similar thickness to cold-rolled plates, and their appearance is obviously different.

Angle steel: all hot rolled.

Steel pipe: both welded, hot rolled and cold drawn.

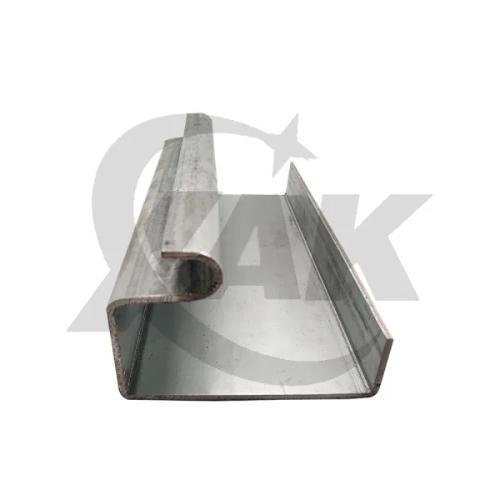

Channel steel and H-shaped steel: hot rolled.

Steel bar: hot rolled material.

Both hot rolling and cold rolling are processes for forming steel plates or profiles, and they have a great influence on the structure and properties of steel. The rolling of steel is mainly hot rolling, and cold rolling is usually only used to produce steel products with precise dimensions such as small sections and thin plates.

Hot Rolled

The termination temperature of hot rolling is generally 800-900°C, and then it is generally cooled in the air, so the hot rolling state is equivalent to normalizing treatment.

Most steel products are rolled by hot rolling method. Due to the high temperature, the steel delivered in the hot-rolled state has a layer of oxide scale on the surface, so it has certain corrosion resistance and can be stored in the open air.

However, this layer of iron oxide scale also makes the surface of hot-rolled steel rough and the dimensions fluctuate greatly. Therefore, steel with smooth surface, precise dimensions and good mechanical properties must be produced with hot-rolled semi-finished products or finished products as raw materials and then cold-rolled.

Advantage

It can destroy the casting structure of the steel ingot, refine the grains of the steel, and eliminate the defects of the microstructure, so that the steel structure is dense and the mechanical properties are improved. This improvement is mainly reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent. Bubbles, cracks and porosity formed during pouring can also be welded under high temperature and pressure.

Shortcoming

1. After hot rolling, the non-metallic inclusions (mainly sulfides and oxides, as well as silicates) inside the steel are pressed into thin sheets, and stratification occurs. Delamination greatly deteriorates the properties of the steel in tension through the thickness, and there is a possibility of interlaminar tearing as the weld shrinks. The local strain induced by weld shrinkage often reaches several times the yield point strain, which is much larger than the strain caused by the load.

2. Residual stress caused by uneven cooling. Residual stress is the internal self-equilibrium stress without external force. Hot-rolled steel sections of various sections have this kind of residual stress. Generally, the larger the section size of the section steel, the greater the residual stress. Although the residual stress is self-equilibrium, it still has a certain influence on the performance of the steel member under the action of external force. For example, it may have adverse effects on deformation, stability, fatigue resistance, etc.

Cold Rolled

Cold rolling refers to the rolling method of extruding steel with the pressure of rolls at room temperature to change the shape of steel. Although the process also heats up the steel plate, it is still called cold rolling. Specifically, hot-rolled steel coils are used as raw materials for cold rolling, and pressure processing is carried out after pickling to remove scale, and the finished product is hard-rolled coils.

Generally, cold-rolled steel such as galvanized and color steel plates must be annealed, so the plasticity and elongation are also good, and are widely used in automobiles, home appliances, hardware and other industries. The surface of the cold-rolled sheet has a certain degree of smoothness, and it feels smoother to the touch, mainly due to pickling. Generally, the surface finish of the hot-rolled sheet cannot meet the requirements, so the hot-rolled steel strip needs to be cold-rolled, and the thinnest thickness of the hot-rolled steel strip is generally 1.0mm, and the cold-rolled steel strip can reach 0.1mm. Hot rolling is rolling above the crystallization temperature point, and cold rolling is rolling below the crystallization temperature point.

The change of steel shape by cold rolling belongs to continuous cold deformation. The cold hardening caused by this process increases the strength and hardness of hard-rolled coils, and decreases the ductility and plasticity indicators.

For end use, cold rolling deteriorates the stamping performance, and the product is suitable for parts with simple deformation.

Advantage

The forming speed is fast, the output is high, and the coating is not damaged. It can be made into a variety of cross-section forms to adapt to the needs of use conditions; cold rolling can cause large plastic deformation of steel, thereby increasing the yield point of the steel.

Shortcoming

1. Although there is no hot plastic compression during the forming process, there are still residual stresses in the section, which will inevitably affect the overall and local buckling characteristics of the steel;

2. The style of cold-rolled section steel is generally an open section, so that the free torsional stiffness of the section is low. It is easy to twist when it is bent, and it is easy to buckle when it is compressed, and its torsional performance is poor;

3. The wall thickness of the cold-rolled formed steel is small, and there is no thickening at the corner where the plates are connected, and the ability to withstand local concentrated loads is weak.

Steel Profiles Supplier - XAK

XAK offers OEM customized Steel Profile solutions for various industries. We have a team of manufacturers and experts who can work with you to create a solution that meets your specific needs. Our steel profile is made of high-quality materials and is designed to withstand the most demanding applications. Contact us today to learn more about our OEM Customized Steel Profile solutions.