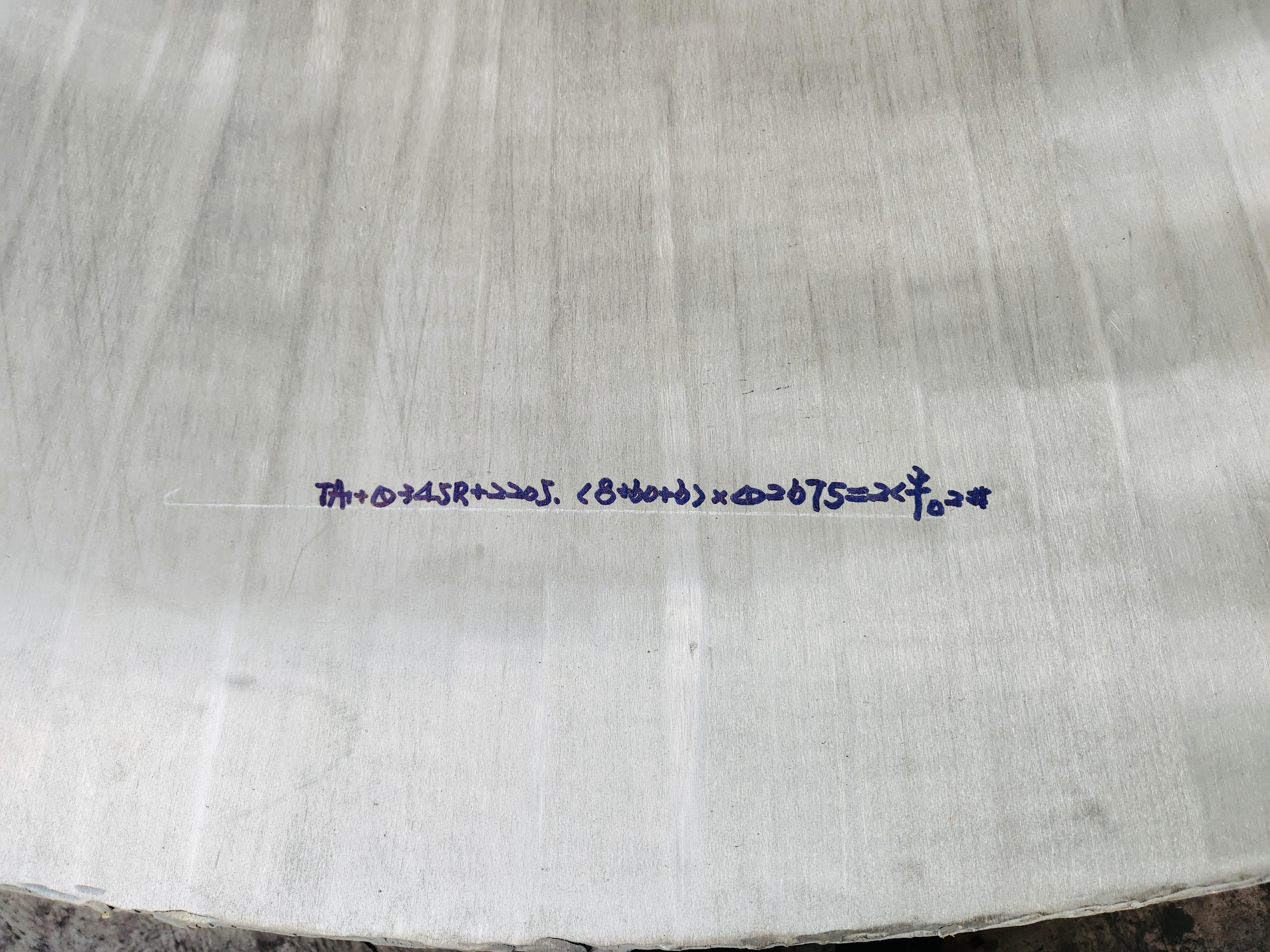

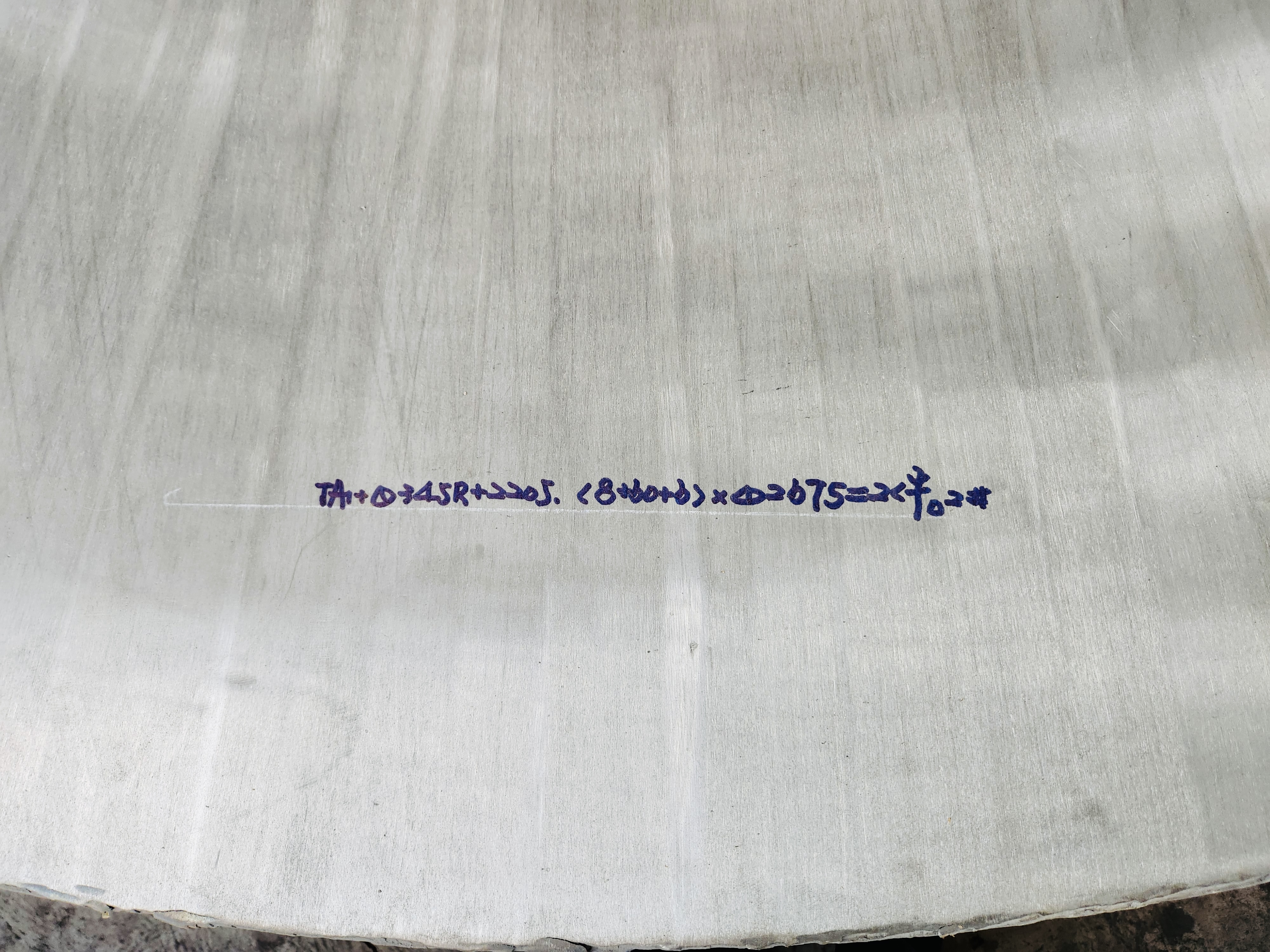

In the realm of advanced materials, titanium steel sheets have emerged as a formidable contender, combining the best properties of both titanium and steel. This unique alloy not only enhances mechanical performance but also offers a range of applications across various industries, from aerospace to medical technology.

Titanium steel sheet, also known as titanium alloy steel sheet, combines the strength and corrosion resistance of titanium with the workability and cost-effectiveness of steel. This hybrid material offers a balanced set of properties that make it ideal for numerous applications. Its unique combination of high strength, low density, excellent corrosion resistance, and good weldability sets it apart from traditional materials.

Exceptional Performance Characteristics

High Strength-to-Weight Ratio

Titanium steel sheet boasts a high strength-to-weight ratio, making it an excellent choice for applications where weight reduction is critical. This characteristic is particularly advantageous in aerospace, automotive, and marine industries, where reducing weight can lead to improved fuel efficiency and performance.

Excellent Corrosion Resistance

One of the standout features of titanium steel sheet is its exceptional corrosion resistance. It resists attack from a wide range of corrosive environments, including saltwater, acids, and alkalis. This makes it ideal for use in chemical processing, marine construction, and oil and gas exploration.

Good Weldability

Titanium steel sheet can be welded using various techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and electron beam welding. Its good weldability allows for the creation of complex and intricate structures without compromising strength or corrosion resistance.

Low Density

With a density approximately 40% less than that of steel, titanium steel sheet is lighter yet equally strong. This makes it an excellent material for applications where weight is a concern, such as in aircraft and spacecraft components.

Biocompatibility

Titanium steel sheet is highly biocompatible, making it a preferred material for medical implants and surgical instruments. Its non-toxic and non-reactive properties ensure that it does not cause adverse reactions in the human body.

Wide-Ranging Applications

Aerospace Industry

In the aerospace industry, titanium steel sheet is used to manufacture aircraft and spacecraft components such as wings, fuselages, and engines. Its high strength-to-weight ratio, corrosion resistance, and good weldability make it an ideal material for these critical applications.

Automotive Industry

The automotive industry leverages the lightweight and strong properties of titanium steel sheet to reduce vehicle weight and improve fuel efficiency. It is used in exhaust systems, suspension components, and engine parts, among others.

Marine Industry

Titanium steel sheet's corrosion resistance and strength make it an excellent choice for marine applications. It is used in shipbuilding, underwater equipment, and offshore structures, where exposure to saltwater and other corrosive environments is inevitable.

Medical Industry

The medical industry relies on titanium steel sheet for its biocompatibility and strength. It is used in implants such as hip replacements, dental implants, and surgical instruments. Its non-reactive properties ensure that it does not cause rejection or other adverse reactions in the human body.

Chemical Processing Industry

In the chemical processing industry, titanium steel sheet's corrosion resistance makes it an ideal material for storage tanks, reactors, and piping systems. It can withstand the harsh environments created by various chemicals, ensuring the safe and efficient operation of chemical plants.

Energy Industry

The energy industry uses titanium steel sheet in applications such as oil and gas exploration, nuclear power plants, and renewable energy systems. Its corrosion resistance and high strength make it suitable for use in extreme environments and high-pressure systems.

Main Features

-

Versatility: Titanium steel sheet's unique combination of properties makes it versatile for a wide range of applications across different industries.

-

Durability: Its high strength and corrosion resistance ensure long-lasting performance, reducing maintenance costs and downtime.

-

Lightweight: The material's low density makes it ideal for applications where weight reduction is critical, leading to improved efficiency and performance.

-

Biocompatibility: Its non-toxic and non-reactive properties make it safe for use in medical applications, ensuring patient safety and satisfaction.

-

Cost-Effectiveness: Compared to pure titanium, titanium steel sheet offers similar performance at a more affordable price point, making it an economically viable option for many applications.

Conclusion

Baoji Smart Metal's titanium steel sheet stands out as a remarkable material due to its exceptional performance characteristics and wide-ranging applications. Its high strength-to-weight ratio, excellent corrosion resistance, good weldability, low density, and biocompatibility make it an ideal choice for numerous industries. As technology continues to advance, the demand for titanium steel sheet is expected to grow, further solidifying its position as a leading material in the global market. Whether you are in the aerospace, automotive, marine, medical, chemical processing, or energy industry, Baoji Smart Metal's titanium steel sheet offers a versatile and cost-effective solution to meet your material needs.