In today’s world, the shift towards sustainability is evident across industries, and the packaging sector is no exception. As companies and consumers become increasingly aware of their environmental impact, eco-friendly alternatives to traditional packaging materials are in high demand. One such material that is gaining traction is molded pulp fiber. Molded pulp fiber is an environmentally responsible packaging solution that is both functional and sustainable. With its potential to replace plastic and other non-recyclable materials, it’s no surprise that molded pulp fiber is being heralded as the future of eco-friendly packaging.

The importance of sustainability in packaging cannot be overstated. Traditional packaging materials like plastic have been causing significant environmental harm for decades, with their non-biodegradable nature contributing to landfill waste, ocean pollution, and the depletion of natural resources. In response to these issues, industries are embracing alternatives such as molded pulp fiber, which is made from renewable resources like recycled paper, cardboard, and other plant-based fibers. As a result, molded pulp fiber offers a promising solution to the packaging crisis and aligns with the global push towards a circular economy.

The Manufacturing Process of Molded Pulp Fiber

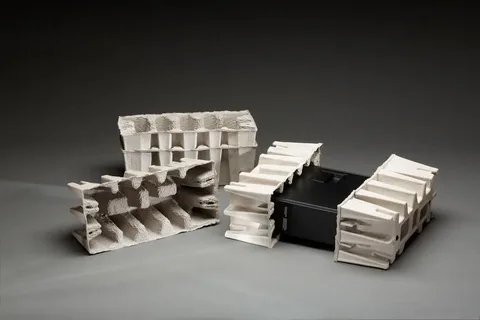

Molded pulp fiber is created through a specialized process that involves the pulping of recycled paper, cardboard, or plant fibers to form a slurry. This slurry is then molded into the desired shape using molds, and it is dried to create the final product. The process is relatively simple yet highly effective in producing packaging that is durable, lightweight, and biodegradable. Unlike plastic or foam packaging, which requires complex chemical processes and energy-intensive methods, the production of molded pulp fiber is much less resource-heavy, making it an environmentally friendly alternative.

The raw materials used in molded pulp fiber production, primarily recycled paper and cardboard, are easily sourced and help reduce the demand for virgin wood. This contributes to the conservation of forests and natural habitats, further enhancing the sustainability of the material. Additionally, the molding process itself can be easily adapted to create custom shapes and sizes, which is an advantage for companies seeking packaging solutions that meet specific product requirements. The versatility of molded pulp fiber makes it suitable for a wide range of applications, from food and beverage packaging to electronics and consumer goods.

Environmental Benefits of Molded Pulp Fiber

One of the key reasons molded pulp fiber is gaining popularity as an eco-friendly packaging solution is its numerous environmental benefits. Unlike plastic, which takes hundreds of years to decompose, molded pulp fiber is biodegradable and compostable. This means that when it reaches the end of its life cycle, it will break down naturally, posing little threat to the environment. Molded pulp fiber also generates significantly less pollution during its production and disposal stages, making it an excellent choice for companies looking to reduce their carbon footprint.

Another environmental benefit of molded pulp fiber is its recyclability. Because it is made from recycled materials, the fiber can be reused to create new products, reducing the need for additional raw materials. This contributes to a circular economy, where products and materials are reused and repurposed, minimizing waste. Furthermore, the pulp molding process consumes less water and energy compared to other packaging production methods, making it a more sustainable choice for businesses that are striving to reduce their environmental impact.

The Versatility of Molded Pulp Fiber Packaging

Molded pulp fiber is incredibly versatile, making it suitable for a wide variety of applications across different industries. Its ability to be molded into various shapes and sizes allows for customized packaging solutions that can accommodate everything from delicate items like eggs and electronics to larger products like food containers and shipping crates. The flexibility of molded pulp fiber ensures that it can meet the unique packaging needs of different businesses, all while maintaining its eco-friendly credentials.

Additionally, molded pulp fiber packaging can be used for both protective and decorative purposes. Its cushioning properties make it an ideal choice for protecting fragile products during shipping, while its ability to be printed on allows businesses to incorporate branding and messaging. Whether used for retail packaging or bulk shipping, molded pulp fiber offers a practical and sustainable solution that can help businesses meet their environmental goals while also enhancing the customer experience.

Molded Pulp Fiber in the Food and Beverage Industry

The food and beverage industry has long been a significant contributor to packaging waste, particularly with the widespread use of plastic containers, single-use cups, and plastic cutlery. However, molded pulp fiber is quickly emerging as a viable alternative to these traditional materials. In fact, many companies in the food industry have already adopted molded pulp fiber for products like takeout containers, drink holders, and egg cartons. The material’s biodegradability and compostability make it a perfect fit for an industry that is under increasing pressure to reduce its environmental footprint.

In addition to being environmentally friendly, molded pulp fiber is also highly functional. It provides a strong, lightweight material for food packaging that can withstand the rigors of transportation and storage while also being safe for use with food. Molded pulp fiber is non-toxic and free from harmful chemicals, making it a safer alternative to plastic containers that can leach chemicals into food. As consumer demand for sustainable packaging increases, molded pulp fiber is becoming an increasingly popular choice for companies in the food and beverage sector looking to align with eco-conscious values.

The Future of Molded Pulp Fiber in Packaging

As more companies embrace sustainability and prioritize eco-friendly packaging solutions, the future of molded pulp fiber looks bright. Innovations in the manufacturing process and the development of new types of pulp fiber materials are expected to further enhance the material’s versatility and performance. Additionally, as consumer awareness grows and regulatory pressures increase, businesses will be motivated to seek out sustainable alternatives to plastic and other harmful packaging materials.

In the coming years, molded pulp fiber has the potential to become the go-to material for a wide range of industries, including cosmetics, electronics, and retail. Its ability to replace traditional packaging materials with a sustainable, recyclable, and biodegradable alternative positions it as a key player in the shift towards a more sustainable economy. As more companies commit to reducing their environmental impact, molded pulp fiber is set to become an essential part of the future of eco-friendly packaging.

In conclusion, molded pulp fiber represents the future of eco-friendly packaging, offering numerous environmental benefits and a high degree of versatility. With its biodegradable, recyclable, and compostable properties, molded pulp fiber is a sustainable alternative to traditional packaging materials like plastic. Its potential for use in a variety of industries, particularly food and beverage, highlights its widespread appeal and importance in the fight against environmental degradation. As the demand for sustainable packaging solutions continues to rise, molded pulp fiber will play a crucial role in reshaping the packaging landscape and creating a more sustainable future for businesses and consumers alike.