Acetyl chloride is a key chemical intermediate widely used in various industrial applications. Its primary use is in the production of acetyl derivatives and as a reagent in organic synthesis. Acetyl chloride is known for its reactivity and versatility, making it an essential component in industries such as pharmaceuticals, agrochemicals, and polymers. With the growing demand for acetyl derivatives and chemical intermediates, establishing an Acetyl Chloride Manufacturing Plant Project presents a lucrative opportunity. This article outlines the critical components, processes, and considerations for setting up such a facility.

Overview of Acetyl Chloride

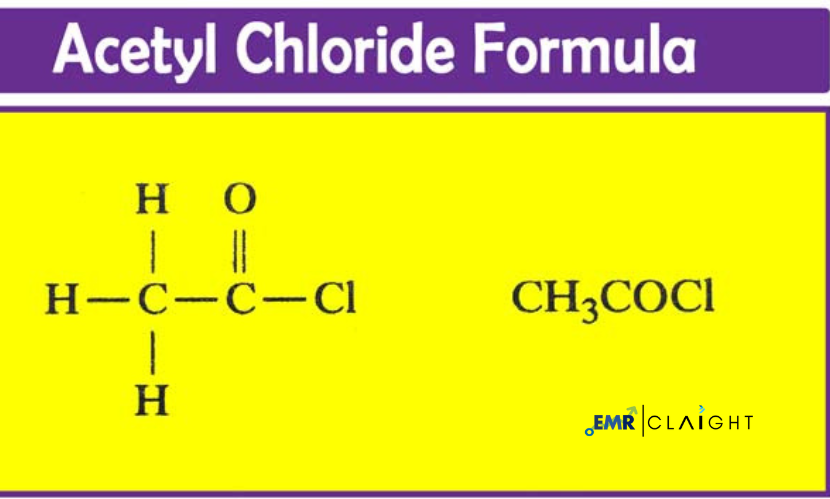

Acetyl chloride is a colourless, pungent-smelling liquid that is highly reactive. It is primarily produced through the reaction of acetic acid with various chlorinating agents. The compound is used extensively in organic synthesis, particularly for acetylation reactions, where it transfers an acetyl group to other molecules. Its applications span across industries, including pharmaceuticals, where it is used to synthesise active pharmaceutical ingredients (APIs), and agrochemicals, where it serves as a precursor for pesticides.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/acetyl-chloride-manufacturing-plant-project-report/requestsample

Benefits of Acetyl Chloride Manufacturing

- High Market Demand: Used extensively in pharmaceuticals, agrochemicals, and chemical synthesis.

- Versatile Applications: Essential for acetylation reactions and the production of derivatives.

- Export Potential: Significant demand in international markets for high-purity acetyl chloride.

- Customisation Opportunities: Ability to produce tailored grades for specific industrial needs.

- Economic Viability: Strong profitability due to its broad applications and consistent demand.

Key Components of an Acetyl Chloride Manufacturing Plant

Establishing a manufacturing plant for acetyl chloride requires advanced equipment and infrastructure to ensure efficient production and high-quality output:

- Raw Material Storage:

- Facilities for storing acetic acid and chlorinating agents such as phosphorus trichloride or thionyl chloride.

- Reaction Chambers:

- Reactors designed for carrying out acetyl chloride synthesis under controlled conditions.

- Distillation Units:

- Systems for purifying acetyl chloride to achieve high-purity standards.

- Cooling Systems:

- Infrastructure to maintain safe temperatures during and after the reaction.

- Packaging Units:

- Automated systems for safely packaging acetyl chloride in secure containers.

- Quality Control Laboratory:

- Facilities for testing raw materials, intermediates, and final products for compliance with industry standards.

Manufacturing Process

The production of acetyl chloride involves several precise steps to ensure high-quality output:

- Raw Material Preparation:

- Acetic acid and chlorinating agents are measured and prepared in the required proportions.

- Chemical Reaction:

- The raw materials undergo a controlled reaction in a sealed reactor to produce acetyl chloride.

- Distillation:

- The reaction mixture is distilled to separate acetyl chloride from by-products and impurities.

- Cooling:

- The purified acetyl chloride is cooled to maintain stability and safety.

- Quality Testing:

- Samples are tested for purity, reactivity, and compliance with industry standards.

- Packaging and Storage:

- The final product is packaged in moisture-resistant containers and stored in appropriate conditions for distribution.

Factors to Consider for Plant Setup

When establishing an acetyl chloride manufacturing plant, several critical factors must be addressed:

- Location:

- Proximity to raw material suppliers and transportation hubs reduces logistics costs.

- Technology:

- Investing in advanced reaction and distillation systems ensures efficient production.

- Regulatory Compliance:

- Adherence to environmental, safety, and quality regulations is essential for market approval.

- Infrastructure:

- Reliable utilities, including electricity, water, and waste management systems, are necessary for smooth operations.

- Workforce:

- Skilled personnel are required to manage chemical reactions, quality control, and packaging processes.

Market Potential

The market for acetyl chloride is robust and growing, driven by its extensive applications in various industries. Key factors influencing market potential include:

- Pharmaceutical Industry:

- Used in the synthesis of active pharmaceutical ingredients and intermediates.

- Agrochemicals:

- Essential for producing pesticides and herbicides.

- Polymers and Plastics:

- Plays a role in the production of acetylated derivatives used in polymer synthesis.

- Global Expansion:

- Export opportunities in regions with high demand for specialty chemicals.

- Research and Development:

- Growing applications in chemical synthesis and material science.

Challenges in Acetyl Chloride Manufacturing

While the production of acetyl chloride offers significant opportunities, certain challenges must be addressed:

- Raw Material Costs:

- Fluctuations in the prices of acetic acid and chlorinating agents can impact profitability.

- Safety Concerns:

- Handling and processing of reactive chemicals require strict safety protocols.

- Regulatory Requirements:

- Ensuring compliance with stringent environmental and safety standards is critical.

- Quality Consistency:

- Maintaining uniform quality across batches is essential for customer satisfaction.

Applications of Acetyl Chloride

Acetyl chloride is a versatile compound with applications across various industries:

- Pharmaceuticals:

- Used to synthesise active pharmaceutical ingredients and chemical intermediates.

- Agrochemicals:

- Plays a key role in the production of pesticides and herbicides.

- Chemical Synthesis:

- Acts as a reagent for acetylation reactions in organic chemistry.

- Polymer Industry:

- Used in the production of acetylated derivatives for polymer synthesis.

- Laboratories:

- Employed as a reagent in research and development.

Future Prospects

The increasing demand for specialty chemicals and the expansion of end-use industries ensure a promising future for acetyl chloride manufacturing. By focusing on quality, sustainability, and innovation, manufacturers can tap into growing markets and establish a strong presence in the chemical industry.