In the vast ocean of modern technology, there is a mysterious and powerful material - NdFeB magnets, which has become an important cornerstone of scientific and technological development with its excellent performance and wide application. From micro-components of electronic products to the core power of large mechanical equipment, NdFeB magnets are silently playing an irreplaceable role.

Neodymium iron boron magnets, also known as NdFeB magnets, are tetragonal crystals composed of elements such as neodymium, iron, and boron. The magnetic energy product (BHmax) of this magnet far exceeds that of other common magnets, making it one of the materials with the largest magnetic energy product in the world. Its discovery can be traced back to 1982, when it was discovered by Masato Sagawa of Sumitomo Special Metals of Japan, and has been widely used and developed in the following decades.

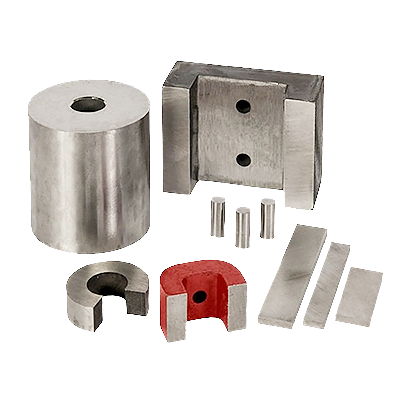

There are two main preparation processes for NdFeB magnets: powder metallurgy and spin-spray melting. Both methods can produce high-performance NdFeB magnets, but each has its own advantages and disadvantages. Powder metallurgy is suitable for preparing magnets with complex shapes, while spin-spray melting is more suitable for preparing large magnets.

NdFeB magnets have been widely used in various fields due to their high magnetic energy product, high coercive force and good stability. In the field of electronic products, NdFeB magnets are widely used in the manufacture of hard disks, mobile phones, headphones and other products, providing these products with strong magnetic properties. In the field of mechanical equipment, NdFeB magnets are used to manufacture core components such as high-performance motors and sensors, providing stable power support for the operation of mechanical equipment.

In addition, NdFeB magnets also play an important role in medical, energy, transportation and other fields. For example, in the medical field, NdFeB magnets are used to manufacture magnetic resonance imaging equipment (MRI), providing important technical support for the diagnosis and treatment of diseases. In the energy field, NdFeB magnets are used in the manufacture of wind turbines, improving the power generation efficiency of wind turbines. In the field of transportation, NdFeB magnets are used to manufacture components such as motors and sensors for electric vehicles, providing important support for the development of electric vehicles.

With the continuous advancement of science and technology and the continuous expansion of applications, the market demand for NdFeB magnets is also increasing. According to statistics, China, as the world's largest NdFeB producer, has seen its output increase year by year, and market demand has also shown a steady growth trend. In the next few years, with the rapid development of new energy vehicles, wind power generation and other fields, the market demand for NdFeB magnets will further increase.

At the same time, with the continuous advancement of technology and the reduction of costs, the application areas of NdFeB magnets will continue to expand. In the future, NdFeB magnets are expected to be used in more fields and become the core power of more products and equipment.

As a high-performance magnetic material, NdFeB magnets play an irreplaceable role in modern science and technology. Its wide application and continuous development have not only promoted the advancement of science and technology and the development of industry, but also made important contributions to the progress and prosperity of human society. In the future, with the continuous advancement of technology and the continuous expansion of application fields, the market prospects of NdFeB magnets will be broader.