The integration of vision systems into traditional web guiding processes marks a substantial advancement in precision manufacturing. Unlike conventional methods relying on mechanical sensors or manual adjustments, vision systems offer improved accuracy and flexibility, essential for modern production operations. By incorporating cameras and image processing algorithms, these systems provide real-time monitoring and adaptive control capabilities, significantly enhancing precision and efficiency. This article explores the integration of vision systems in web guiding, shedding light on their transformative impact across various industries.

The Role of Vision Systems in Web Guiding

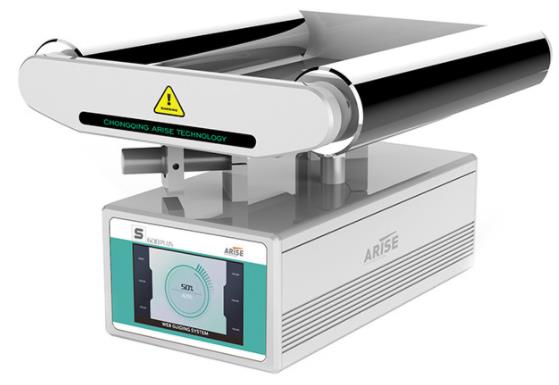

Vision systems, comprising cameras and image processing algorithms, excel at capturing and analyzing visual information in real-time. By continuously monitoring the location and alignment of web content, they offer precise input to guiding mechanisms, facilitating dynamic adjustments to maintain proper alignment. Unlike mechanical sensors prone to limitations or wear, vision systems boast greater flexibility and accuracy, making them indispensable for applications demanding precise alignment.

Key Benefits of Integrating Vision Systems in Web Guiding Processes

Precision:

Vision systems provide high-resolution imaging and advanced algorithms for accurate alignment identification and analysis. By precisely tracking the location and orientation of web material, they minimize misalignment-related faults, ensuring high-quality output.

Real-time Monitoring:

Continuous monitoring of web content position and movement enables immediate identification of deviations or abnormalities, allowing swift corrective action to maintain synchronization. Real-time monitoring reduces material waste and minimizes manufacturing errors.

Adaptive Control:

Vision systems facilitate adaptive control of guiding mechanisms based on real-time feedback. By dynamically adjusting parameters like speed, angle, or tension, they respond to changes in material properties or production conditions, ensuring consistent alignment and performance.

Versatility:

Vision systems can be tailored to accommodate various web materials and production processes. Adaptable and easily integrated, they offer versatility across industries, making them suitable for diverse applications.

Reduced Downtime:

Early detection of alignment issues or defects minimizes downtime associated with manual inspection. Vision systems enable timely interventions and preventive maintenance, mitigating the risk of production stoppages and equipment damage.

Data Insights:

Capturing valuable data on material alignment trends and production parameters, vision systems facilitate process optimization and quality control. Insights gained enable continuous improvement of web guiding processes and production efficiency.

Improved Safety:

Vision web guide systems reduce manual intervention, minimizing the risk of accidents associated with handling materials or machinery. By automating the guiding process, they contribute to a safer working environment for operators and maintenance personnel.

Future Trends and Innovations of Vision Systems in Web Guiding Processes

Enhanced Artificial Intelligence (AI) Integration:

Advanced AI techniques will enhance vision systems' capabilities, enabling them to evaluate vast amounts of visual data in real-time and autonomously modify guiding parameters for increased precision and effectiveness.

Multi-Spectral Imaging:

Integration of multi-spectral imaging will enhance material characterization and defect detection, particularly in applications with diverse materials and surface properties.

3D Vision and Depth Sensing:

Incorporating 3D vision and depth sensing technologies will enable more accurate detection of surface irregularities and enhance defect detection capabilities.

Edge Computing and Real-Time Processing:

Leveraging edge computing will enable faster response times and more efficient processing of visual data, enhancing system responsiveness and adaptability.

Integration with Robotics and Automation:

Integration with robotics will enable autonomous web guiding in dynamic production environments, enhancing efficiency and productivity.

Augmented Reality (AR) Interfaces:

AR interfaces will provide operators with user-friendly tools for managing web guiding procedures, improving user interaction and situational awareness.

Sustainability and Energy Efficiency:

Vision systems will prioritize eco-friendly materials and energy-efficient design, promoting sustainable manufacturing practices and waste reduction.

Conclusion

The integration of vision systems into web guiding processes represents a significant advancement in precision manufacturing. Across industries, these systems revolutionize production processes, enabling manufacturers to achieve higher quality, efficiency, and competitiveness. With ongoing advancements and innovations, vision-guided web guiding systems are poised to play a pivotal role in shaping the future of manufacturing.