From its origins to its current uses, it has a rich history that is worth examining manufacturing cnc.

In today's rapidly evolving manufacturing industry, CNC machining has emerged as a game-changer. With its precise and efficient capabilities, CNC machining has revolutionized modern manufacturing processes. This article delves into the various benefits of CNC machining and its impact on the industry.

Enhanced Precision and Accuracy

One of the key advantages of CNC machining in modern manufacturing processes is its ability to deliver unparalleled precision and accuracy. Unlike traditional manual machining, CNC machines are controlled by computer programs, ensuring consistent and precise results. The use of computer-aided design (CAD) software allows for intricate designs to be translated into precise instructions for the CNC machine, resulting in flawless end products.

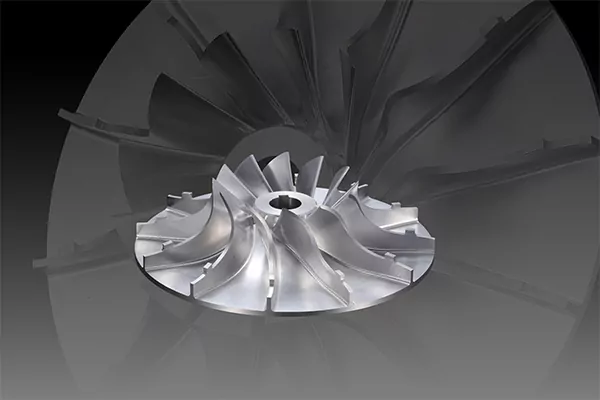

For example, in the aerospace industry, where precision is of utmost importance, CNC machining plays a vital role in manufacturing critical components such as turbine blades. The ability to achieve tight tolerances and intricate geometries ensures optimal performance and safety.

Increased Efficiency and Productivity

CNC machining significantly improves efficiency and productivity in modern manufacturing processes. The automation and programmability of CNC machines eliminate the need for manual intervention, reducing human error and increasing production speed. Once the initial setup is complete, CNC machines can operate continuously, 24/7, without the need for constant supervision.

Furthermore, CNC machines can perform multiple operations simultaneously, such as milling, drilling, and turning, in a single setup. This multitasking capability streamlines the manufacturing process, reducing production time and costs. As a result, manufacturers can meet tight deadlines and deliver products to market faster.

Flexibility and Versatility

CNC machining offers unparalleled flexibility and versatility in modern manufacturing processes. With the ability to quickly change tooling and reprogram the machine, manufacturers can easily switch between different product designs and specifications. This adaptability is particularly beneficial in industries where customization and rapid prototyping are essential.

For instance, in the automotive industry, CNC machining allows manufacturers to produce various components with different shapes, sizes, and materials. Whether it's engine parts, interior components, or exterior body panels, CNC machines can handle the diverse requirements of the industry.

Improved Safety and Risk Mitigation

CNC machining enhances safety in modern manufacturing processes by minimizing the risk of accidents and injuries. With manual machining, operators are exposed to potential hazards such as sharp tools, flying chips, and rotating machinery. CNC machines, on the other hand, operate in a closed and controlled environment, reducing the risk of operator injuries.

Additionally, CNC machines can be equipped with advanced safety features such as automatic tool breakage detection and emergency stop buttons. These safety measures further mitigate risks and ensure a secure working environment for operators.

Exploring the benefits of CNC machining in modern manufacturing processes reveals its transformative impact on the industry. From enhanced precision and accuracy to increased efficiency and productivity, CNC machining offers a wide range of advantages. Its flexibility, versatility, and improved safety make it an indispensable tool for manufacturers across various sectors. As technology continues to advance, CNC machining will undoubtedly play a pivotal role in shaping the future of manufacturing.