Biomass Pellet Output Line

Biomass Pellet Generation Line turns farming or industrial waste products into hard pellets which can be used as gas for heating plus power generation. They are regarded as being clean and alternative, burning less compared to fossil fuels as well as emitting less carbon dioxide during combustion. The employment of these alternative vitality sources helps reduce reliance upon foreign oil along with the resulting environmental personal injuries. The raw material for biomass pellets may be recycled from farming or industry, which saves funds and space in landfill sites and keeps the price of the pellets lower. The raw materials could be packaged in 960 kg as well as one tonne carriers, or shipped in bulk.

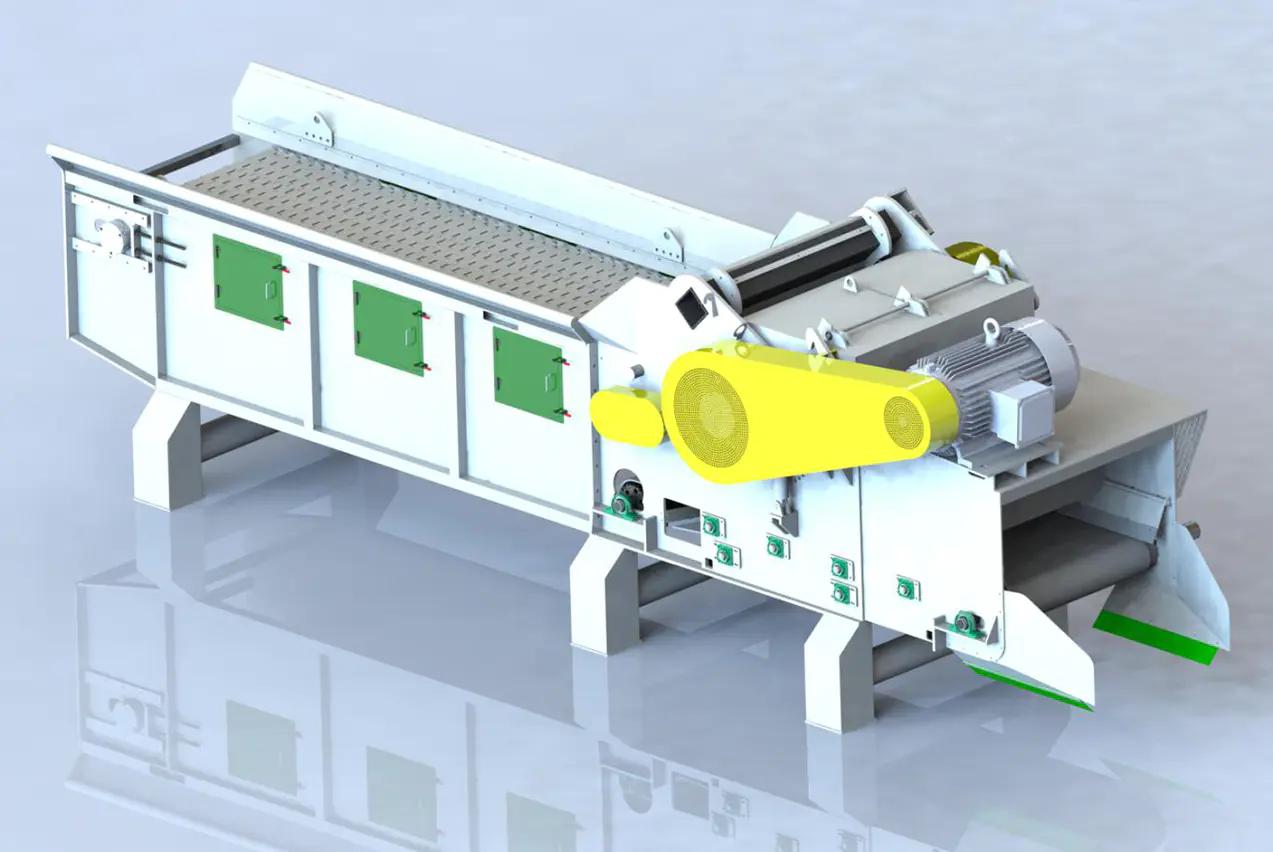

The means of making the biomass pellets consists of several steps. The initial step is to take out any contaminants with the raw material by using a grinder and screener. This is done to guarantee that there are no stones or even metal pieces inside the final product. The raw stuff is then pulverized to make it smaller and easier to deal with. The pulverized uncooked material is then mixed that has a natural binding agent to assist hold the pellets together through compression process.

Another important factor while in the biomass pellets creation process is ensuring the moisture content of the raw materials is low enough to allow for for proper granulation. Depending on any type of raw material, this is often accomplished by by using a wood chipper and also hammer mill to break up the raw components and reduce their own size, then drying them in a pelletizer dryer that will bring the moisture level as a result of about 15%.

Once the binder is put into the raw materials and the moisture is lowered, the next step could be to press the content into pellet form employing a horizontal ring perish pellet machine. This ring die functions friction to compress the materials, forcing them through holes designed into the idea. The resulting pellets tend to be about 6 mm throughout diameter and 40 mm long. They're just then packed in bags or shipped to customers throughout bulk.

Before being used as fuel to the pellets, China Vertical Pellet Machine Manufacturers the biomass pellets tend to be screened again to make sure that they are free of foreign matter. The screened pellets may be sold in modest bags or within bulk to individuals for use to be a source of fresh, green fuel.

The raw materials required for biomass pellet manufacturing are relatively cheap and easily obtainable in many international locations, particularly those along with an agricultural financial state. It is in addition a renewable learning resource, which means that it is definately depleted any occasion soon. However, the buying price of biomass pellets is dependent upon the quality as well as the types of natural materials used. In addition, the pellets have a limited lifespan, which can result in costly replacement expenses. Therefore, it may be beneficial to invest in a couple of pellet machine so that if any advisors breaks down, one other can continue functioning. This will make sure the business can still build a steady supply involving pellets and avoid lost revenue.