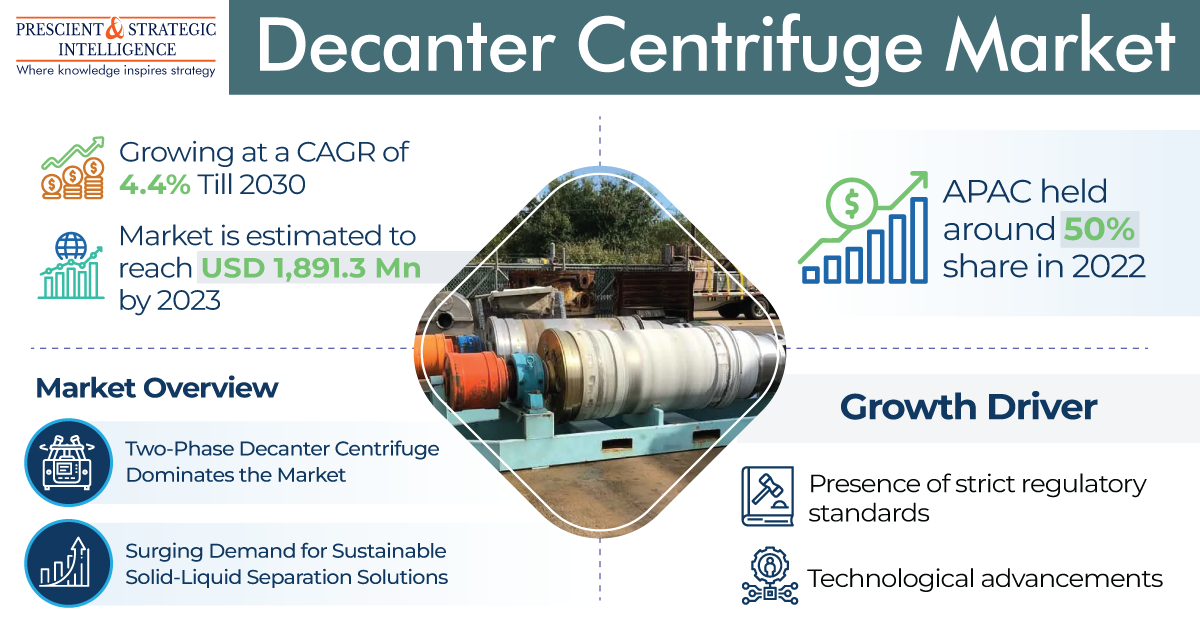

In 2022, the global decanter centrifuges market revenue is estimated to rise to USD 1 811.1 million and grow at a 4.4% compound annual growth rate between 2023 and 2030, reaching a value of USD 2 561.1 million by 2030.

This growth of the market can be credited to the increasing demand for decanter centrifuges in sectors, the existence of hard-and-fast regulative standards in the case of product making, technical progression, and the rising demand for pharmaceutical separation in the food and beverage sector.

There is a surge in the need for streamlined solid-liquid separation solutions, as sectors globally such as wastewater management, oil & gas, food processing, and wastewater management demand the ideal approaches for separating solids from liquids, and decanter centrifuge provides this service at the best level.

On the basis of type segment, the industry is segmented into three-phase decanter and two-phase decanter. The two-phase decanter category grips the largest income share, credited to its extensive applications in many sectors. Also, this centrifuge is required to separate solid and liquid in the waste management, food processing, oil and gas drilling, manufacturing, and hemp industries.

On the basis of design type, the industry is divided into vertical and horizontal decanter centrifuges. Which, the horizontal category grips a considerable share in the market, credited to its widespread usage and increasing popularity.

Whereas, in view of the fact that these items are utilized very specifically, it is projected that the vertical segment will advance significantly during the projection. The rotating unit shall be connected vertically to its weight, which shall be handled by a single bearing at the bottom, in a vertical decanter centrifuge. The gearbox and bowl are hung from the drive head, which is attached to the frame.

Due to the orientation and rotation seals installed at one end of the vertical decanter, it is capable of operating above temperatures up to 800C. This type of structure makes it more expensive than the contrary one.

Worldwide, the APAC industry is dominating with the largest revenue share and the region is also projected to observe the fastest development in the coming few years. This is mainly because of increasing end-use sectors, like manufacturing, chemical, wastewater, and pharmaceutical, in the region.

In the APAC region, China is leading the market, mainly because it has a well-developed manufacturing sector throughout the world and also has dominance in the making of power, steel, cement, chemical petrochemical, and refining industries. Moreover, Japan recently became one of the world’s major manufacturing hubs, credited to the rise in manufacturing processes and the availability of decanter centrifuges in the nation.