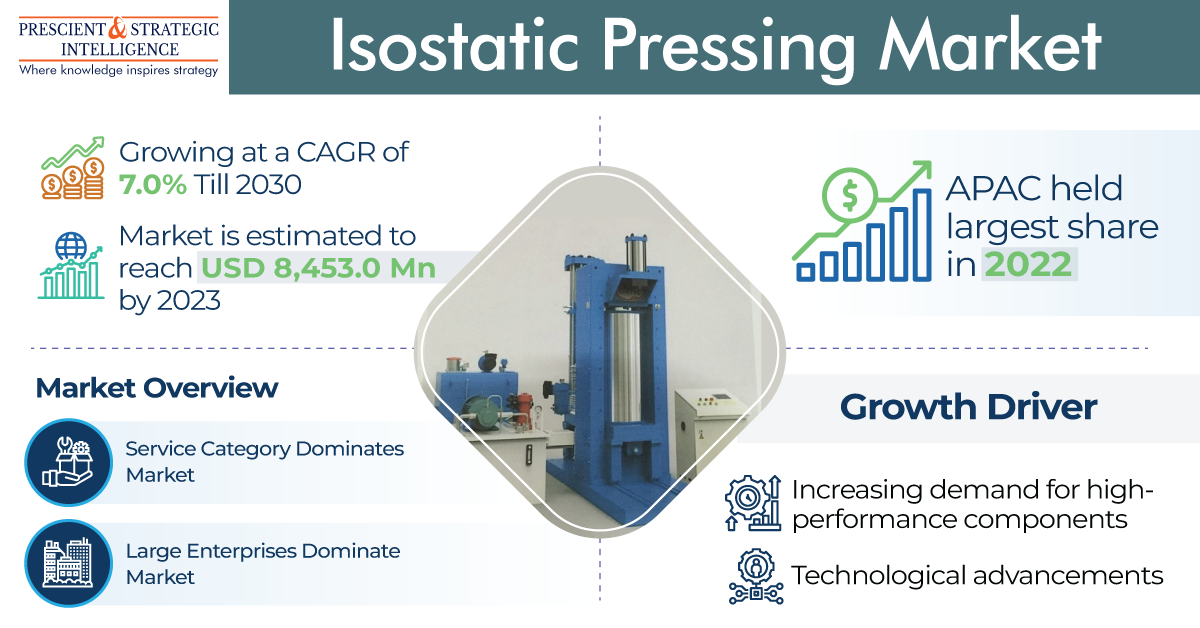

The global isostatic pressing market is projected to be USD 13,568.1 million by 2030 growing at a CAGR of 7.0% during the forecast period. sectors including energy, aerospace, medical devices, automotive, and manufacturing regularly use isostatic pressing.

In this regard, the requirement for such technology is significantly impacted by the growing requirement for contemporary materials and components with brilliant features, like homogeneity, high density, and mechanical strength.

The service category grips the larger industry share, as services are vital for the optimization, operation, maintenance, and associated machinery. The installation and commission of isostatic presses should be done correctly, to guarantee determined productivity. Installation services comprise integrating, setting up, and calibrating the present manufacturing infrastructure with the novel equipment.

Numerous IP devices, like hot isostatic presses, high-pressure systems, cold isostatic presses, and their subsidiary parts are comprised in the systems category. To attain consolidation and expansion, such machines put even pressure on materials from every side. Reliant on the application and material needs, such systems utilize a variety of pressure mediums, such as water, oil & gases. The system is made and set up precisely for the particular pressure medium.

The HIP category has a substantial Isostatic Pressing Market share mainly because this technology is extensively used. medical devices, aerospace, automotive, power, and numerous more businesses can profit from HIP's flexibility and applicability. It is suitable for a range of applications as it might be utilized to combine and densify a variety of materials, such as composites, metals, ceramics, and powders.

Large-scale industries regularly spend on bigger and more complex isostatic pressing systems to handle advanced production sizes, because of their robust economic resources, infrastructure, and well-known industry existence. This is the major factor for having the largest share by the large enterprise category.

For a count of factors, the APAC region leads the industry for isostatic pressing. First, the requirement for this technology has increased due to the region's escalating industrial sector, mainly in India, China, South Korea, and Japan. Second, the APAC region has a substantial existence in sectors such as aerospace, automotive, energy, and electronics, which deeply depend on IP.

The technology in manufacturing, specifically isostatic pressing, has also advanced significantly in APAC in recent years. The region has become a worldwide front-runner in technology because of the expenditure on research and development and corporations between researchers and businesses. The region now has a larger need for IP because of the increasing demand for urbane materials, like ceramics, high-strength alloys, and composites.