In industrial scenarios where high temperatures, corrosive media, and the demand for precision filtration are increasing day by day, traditional filtration materials often fail to meet the harsh working conditions. Metal filter elements have become "key components" in the industrial filtration field due to their high-temperature resistance (900℃), corrosion resistance and precise filtration (0.1μm) characteristics. It is mainly divided into high-temperature metal membrane filter bags, metal powder sintered filter elements, sintered mesh filter elements, sintered felt filter elements, etc.!

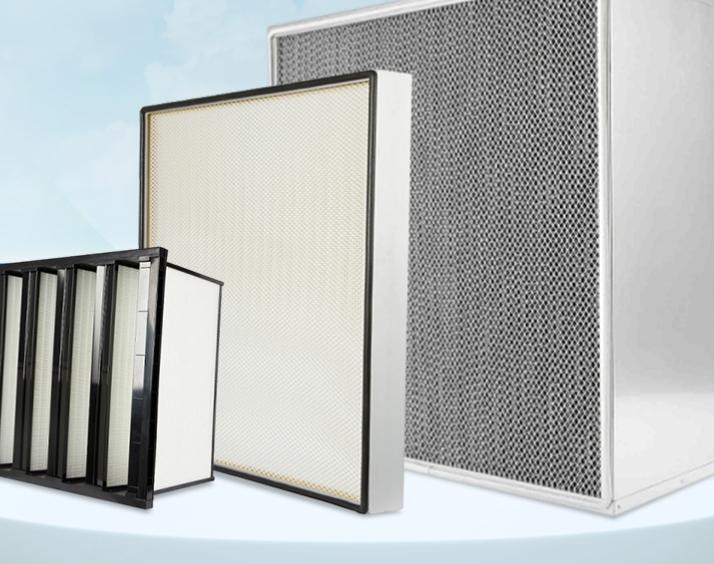

Application scenarios of self-support panel filter:

Metallurgy and power: High-temperature metal membrane filter bags effectively remove dust from the flue gas of smelting furnaces and boilers, and support stable operation under the premise of complying with equipment operation specifications.

Chemical and petrochemical industries: Metal powder sintered filter elements and sintered felt filter elements are suitable for high-temperature gas filtration and support production safety requirements.

Environmental protection and electronics: Sintered mesh filter elements intercept micron-sized particles in semiconductor manufacturing, supporting product yield control.

Food and pharmaceuticals: Powder sintered filter elements undergo sanitary-grade filtration, effectively reducing liquid impurities.

self-support panel filter https://www.ast-filter.com/Self-support-Panel-Filter.html