External Cavity Diode Lasers (ECDLs) are prized for their ultra-narrow linewidth, making them essential in precision applications like atomic clocks, quantum optics, and coherent communications. However, achieving sub-kHz linewidths requires more than just a well-designed cavity—temperature stabilization plays a critical role. This blog explores how thermal management impacts linewidth and the techniques used to minimize frequency noise.

The Impact of Temperature Fluctuations on Linewidth

Even minor temperature changes (as small as 0.01°C) can induce cavity length variations, leading to frequency drift and linewidth broadening. Two primary effects occur:

Thermal Expansion of the Cavity – The physical expansion/contraction of materials (e.g., aluminum, invar) alters the optical path length.

Diode Wavelength Shift – The laser diode’s emission wavelength is temperature-dependent (~0.1 nm/°C for typical diodes).

Without stabilization, these effects introduce phase noise, degrading coherence.

Key Stabilization Techniques

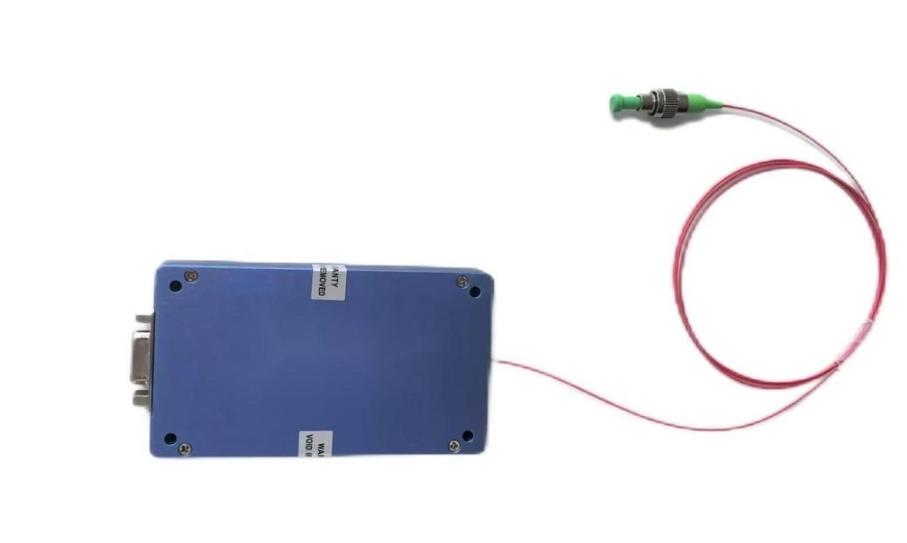

Thermo-Electric Coolers (TECs) – Most ECDLs integrate TECs with PID control to maintain diode and cavity temperatures within milli-Kelvin precision.

Low-Expansion Materials – Invar or carbon fiber is often used for cavity construction to minimize thermal drift.

Double-Stage Isolation – High-performance systems use nested thermal enclosures to reduce ambient fluctuations.

Case Study: Impact on Linewidth

A study comparing free-running vs. stabilized ECDLs showed:

Uncontrolled: Linewidth > 1 MHz (dominated by thermal drift).

Stabilized: Linewidth < 10 kHz (with active TEC + passive isolation).

Conclusion

Temperature stabilization is non-negotiable for achieving narrow linewidths in ECDLs. Advances in PID algorithms and low-CTE materials continue to push the limits, enabling sub-Hz performance in lab-grade systems.