Injection pallet moulds play an important role in the production of plastic pallets widely used in logistics, storage, and transportation industries. Their design and performance characteristics contribute to efficient and consistent pallet production, offering various practical benefits for manufacturers and end-users alike.

One notable advantage of injection pallet moulds is their ability to deliver uniform and repeatable results. Through precise cavity structures and well-planned ejection systems, these moulds ensure that each pallet produced maintains consistent dimensions and surface quality. This reliability is essential in industries where pallets are required to meet specific load-bearing and stacking standards.

Another important feature lies in the durability of the mould itself. Typically made from carefully selected high-strength steel, injection pallet moulds are built to withstand high-pressure production cycles. This helps reduce maintenance frequency and supports stable long-term operation, contributing to overall production efficiency.

The cooling system within an injection pallet mould is another valuable aspect. By incorporating strategically positioned cooling channels, the mould helps manage temperature control during the injection process. This contributes to shorter cycle times and minimizes the risk of product deformation, resulting in smoother and more consistent pallet surfaces.

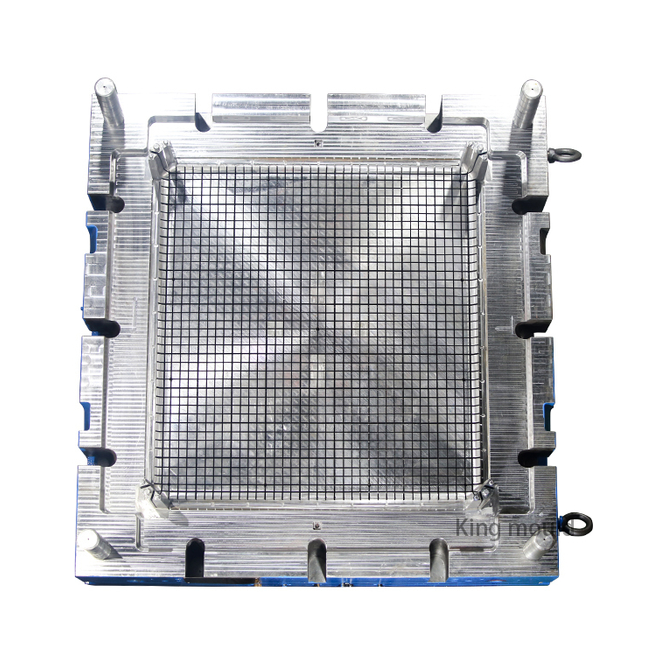

Injection pallet moulds also offer a degree of flexibility in terms of customization. Manufacturers can adjust features such as grid patterns, pallet size, and structural designs according to specific operational needs. This makes it possible to create pallets suited for different applications, whether for food storage, pharmaceutical transport, or heavy-duty logistics operations.

Ease of maintenance is another characteristic often considered in the design of these moulds. Modular components and accessible layouts allow for efficient cleaning, inspection, and part replacement when necessary. This helps maintain consistent performance while reducing downtime in production lines.

In summary, injection pallet moulds provide practical advantages such as product consistency, material durability, effective cooling systems, customization options, and straightforward maintenance. These features make them a reliable choice for producing pallets that meet the diverse demands of modern logistics and storage operations.