Solar screen mesh fabric is a specialized material designed to reduce solar heat gain, glare, and UV radiation while maintaining outward visibility. Its primary application is in architectural shading systems, such as exterior roller shades, window screens, and patio enclosures. To perform well in these functions, the composition and structure of the material play a critical role.

The core materials used in solar screen mesh fabric are usually polyester or fiberglass yarns. These base fibers are selected for their stability, resistance to environmental conditions, and ability to hold coatings effectively. The mesh structure is designed to block a portion of sunlight while still allowing airflow, creating a balance between shading and ventilation.

Fiberglass is a common base material due to its dimensional stability and resistance to stretching or shrinking under tension or temperature changes. When coated with PVC (polyvinyl chloride), it gains additional protection against moisture, dirt, and UV degradation. This combination allows solar screen mesh fabric to retain its physical integrity after prolonged outdoor use.

Polyester-based mesh fabric is also widely used, especially in applications where additional strength or elasticity is desired. Polyester fibers are known for their toughness and resistance to abrasion, which can be beneficial in high-wind environments or areas prone to mechanical wear. Like fiberglass, polyester is often coated with PVC to improve weather resistance and extend the usable life of the product.

The openness factor is a defining characteristic of solar screen mesh fabric. This refers to the percentage of open space in the mesh that allows light and air to pass through. A fabric with a lower openness factor provides more shading and greater UV protection but may reduce visibility and airflow. On the other hand, a higher openness factor allows for better visibility and ventilation but reduces the shading effect. Different settings may require different openness levels based on the desired performance.

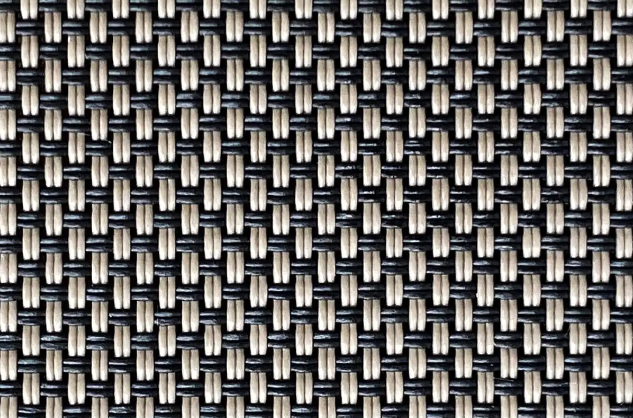

Another key factor is the weave pattern. Plain weave is commonly used for solar screen mesh fabric, offering consistent performance and uniform appearance. Some variations may include basket weave or twill weave, depending on the desired texture, strength, or aesthetic appeal. Regardless of the weave, consistency and even tension are necessary to ensure the fabric performs reliably when installed.

Color selection also impacts the functional properties of solar screen mesh fabric. Darker colors tend to provide better glare control and outward visibility, while lighter colors reflect more heat and light, contributing to indoor brightness. Material suppliers often offer a range of color options to accommodate both performance and design considerations.

Fire resistance is another important attribute, especially for commercial applications. Many versions of solar screen mesh fabric are treated or inherently flame-retardant to meet local building codes and safety standards. Compliance with these requirements can be essential when installing the fabric in public buildings, office complexes, or high-occupancy residential units.

Durability is affected not only by the yarn and coating but also by how the fabric responds to UV exposure, temperature extremes, and moisture over time. Quality solar screen mesh fabric typically includes additives or treatments that resist fading, brittleness, or mildew formation under these conditions.

The performance of solar screen mesh fabric is closely tied to its material composition, openness, weave structure, and finish. Understanding these properties allows architects, builders, and fabricators to select the right type of mesh for a given application. Whether used in commercial shading systems or residential environments, careful consideration of materials ensures that the fabric meets both aesthetic and functional goals.