Cap compression machines play an essential role in the modern packaging industry, especially for beverage, pharmaceutical, and household product sectors. Among the global manufacturing hubs, China has developed a strong presence in the design and production of cap compression machines, offering reliable solutions for businesses aiming to improve their packaging operations.

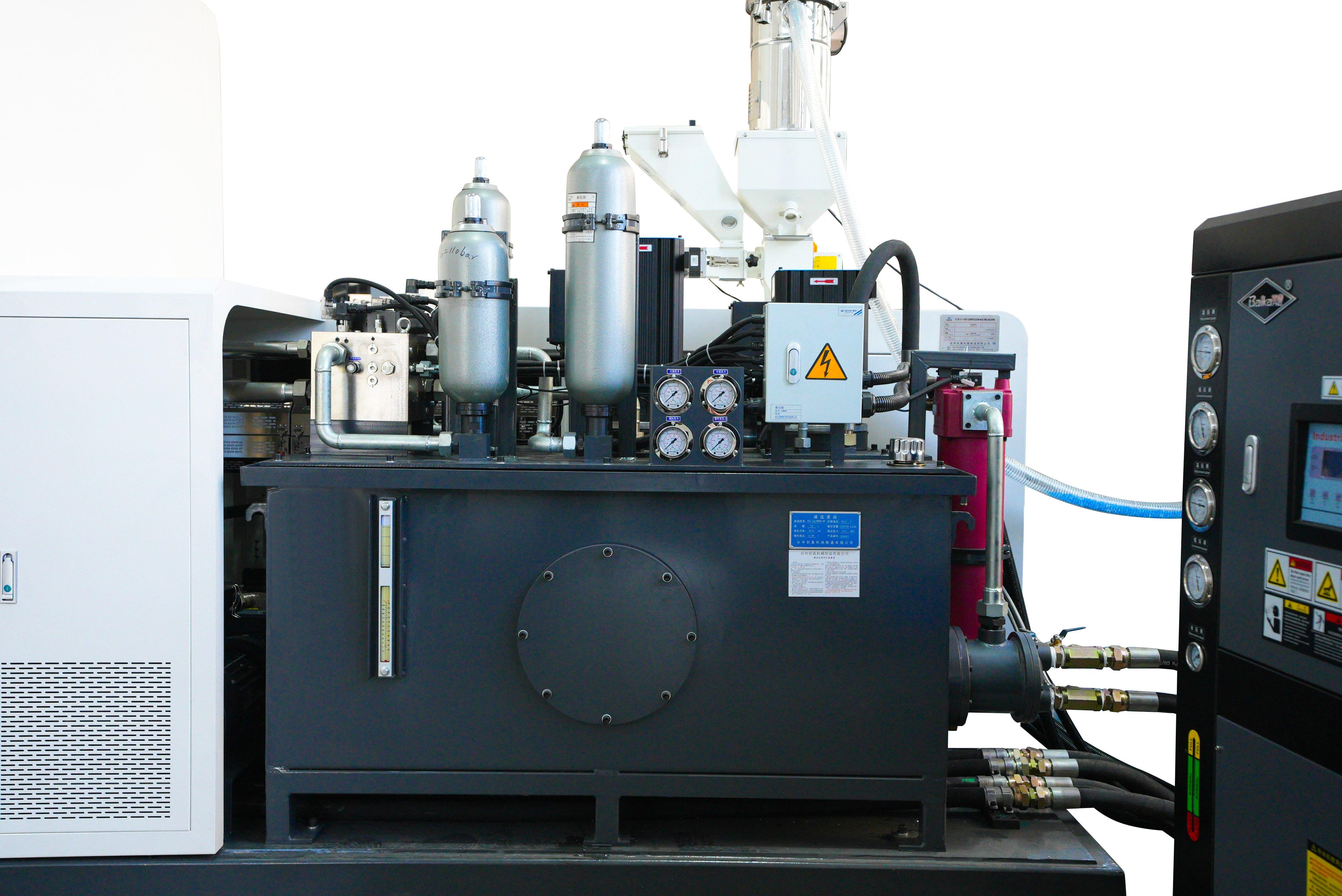

From a manufacturer’s point of view, producing cap compression machines involves careful attention to both structural design and functional performance. Each component must be engineered to support continuous, stable operation while accommodating high-volume production demands. In China, cap compression machine manufacturers focus on optimizing production efficiency, equipment durability, and ease of maintenance to meet the diverse needs of international clients.

One of the key areas manufacturers address is material control. By refining the compression molding process, it is possible to reduce material consumption without affecting the essential performance characteristics of the bottle cap. Many modern machines achieve this by adjusting mold designs and optimizing the thickness of the cap while preserving its sealing quality. This approach supports businesses in managing raw material costs while maintaining product standards.

Another important aspect for manufacturers is the stability of machine operation. Cap compression machines produced in China are designed for consistent performance over extended periods. With improvements in mechanical components, servo systems, and control panels, machines can maintain a high uptime rate under continuous working conditions. Field testing at various production sites helps manufacturers verify performance data and make adjustments based on actual working environments.

China-based manufacturers also place emphasis on offering flexible configurations. Different industries require different cap designs, sizes, and materials. By providing a range of mold sets and adjustable settings, a cap compression machine can meet a wide range of production specifications. This versatility helps factories quickly adapt to market changes without the need for significant equipment modifications.

Additionally, ease of operation and maintenance is a priority. Many machines feature user-friendly interfaces and modular components, allowing operators to perform routine checks and maintenance tasks with minimal downtime. Manufacturers also offer technical support services, ensuring that any operational issues can be addressed efficiently, keeping production lines running smoothly.

In summary, the production of cap compression machines in China is characterized by attention to efficiency, material control, machine reliability, and adaptability. Manufacturers continuously gather feedback from operational sites to improve their product designs and deliver equipment that aligns with the practical needs of global clients. As packaging requirements evolve, China’s cap compression machine manufacturers remain focused on providing stable, efficient, and serviceable solutions for businesses across multiple industries.