In today's fast-paced manufacturing and distribution environments, efficiency is paramount. Companies are constantly seeking innovative solutions to streamline processes, reduce labor costs, and enhance productivity. The automatic case erector, a cornerstone in modern packaging lines, revolutionizes efficiency by swiftly assembling and erecting cardboard boxes with precision. Among the leading providers in this field is SICIAUTO, renowned for its cutting-edge technology that ensures high-speed, reliable performance. SICIAUTO's automatic case erectors are designed to seamlessly integrate into various packaging workflows, reducing labor costs and enhancing productivity. With their advanced features and robust construction, these machines are pivotal in maintaining the smooth operation of supply chains across diverse industries, from food and beverage to pharmaceuticals, demonstrating SICIAUTO's commitment to innovation and quality in automated packaging solutions.

Introduction to Automatic Case Erector

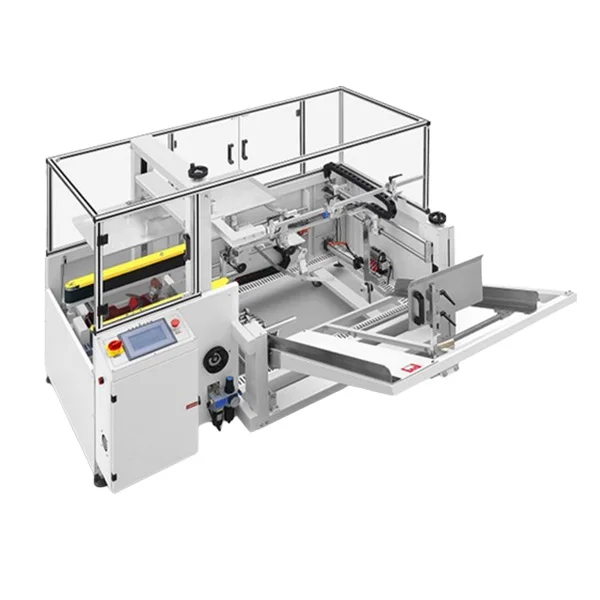

An automatic case erector is a piece of machinery designed to automate the process of forming, erecting, and sealing cardboard boxes. This equipment handles flat, collapsed cartons, transforms them into fully assembled boxes, and often seals the bottom with tape or hot glue. By automating this traditionally manual task, businesses can achieve substantial gains in efficiency and cost savings.

Key Selling Points of Automatic Case Erector

1. High Bulk Productivity in Short Duration

One of the most compelling selling points of the automatic case erector is its capacity for high bulk productivity. In today's market, where speed and volume are critical, manual box assembly can be a significant bottleneck. Automatic case erectors, however, can handle a high volume of cartons in a fraction of the time it would take for human operators. This rapid output allows businesses to keep up with demanding production schedules, ensuring timely delivery of products to customers.

Moreover, the machines are designed to run continuously with minimal downtime, further enhancing overall productivity. This capability is particularly valuable during peak seasons or when fulfilling large orders, as it allows companies to maintain a steady flow of packaged products without compromising quality.

2. Flexibility in Handling Various Box Sizes and Shapes

Another key advantage of automatic case erectors is their versatility in handling a wide range of box sizes and shapes. Modern machines are equipped with adjustable features that allow operators to switch between different carton specifications seamlessly. This flexibility is crucial in diverse manufacturing environments where products come in various packaging requirements.

Whether you need to pack small consumer goods, large industrial parts, or anything in between, an automatic case erector can be configured to meet your specific needs. This adaptability reduces the need for multiple machines or extensive manual adjustments, saving both time and resources.

3. Bottom Sealing with Tape/Hot Glue for Enhanced Stability

Automatic case erectors not only form and erect boxes but also secure their bottoms with tape or hot glue. This feature ensures that the boxes are properly sealed and ready for filling, reducing the risk of damage or leakage during transportation. The use of tape or hot glue provides a strong, reliable seal that can withstand the rigors of shipping and handling.

Moreover, the machines can be programmed to apply the correct amount of adhesive, minimizing waste and ensuring consistent sealing quality. This attention to detail enhances the overall presentation of the packaged product, which can be crucial for maintaining brand image and customer satisfaction.

4. High Demand in Automated Packaging Lines

The increasing demand for automated packaging lines is another significant selling point of automatic case erectors. As businesses strive to automate their entire production processes, the integration of automatic case erectors becomes a natural extension. These machines are designed to seamlessly integrate with other packaging equipment, such as fillers, sealers, and palletizers, creating a streamlined, efficient packaging workflow.

By incorporating automatic case erectors into automated packaging lines, businesses can achieve unprecedented levels of efficiency and productivity. The machines reduce the need for human intervention, minimizing errors and downtime. Furthermore, they enable businesses to scale their operations more easily, adapting to changes in demand without significant disruptions.

Conclusion

In conclusion, automatic case erectors offer a compelling solution for businesses seeking to improve packaging efficiency. Their ability to handle high volumes of cartons in short durations, coupled with their flexibility in handling various box sizes and shapes, makes them indispensable in modern manufacturing and distribution environments. Additionally, the machines' ability to secure box bottoms with tape or hot glue and their seamless integration into automated packaging lines further enhances their appeal.

By investing in SICIAUTO automatic case erectors, businesses can achieve substantial gains in productivity, cost savings, and overall operational efficiency. As the packaging industry continues to evolve, SICIAUTO automatic case erectors will undoubtedly play a pivotal role in driving innovation and competitiveness.