Board to Board Power Connectors are critical components within electronic systems, facilitating the transfer of power between closely spaced circuit boards. Their reliability is paramount to the functionality and longevity of the devices they serve. One environmental factor that significantly influences the performance of these connectors is humidity. This article delves into the effects of varying humidity levels on the reliability of Board to Board Power Connectors.

Humidity, a measure of the amount of water vapor present in the air, can have a profound impact on the electrical performance and physical integrity of Board to Board Power Connectors. High-humidity environments can lead to condensation, which may cause short circuits or corrosion, thereby compromising the connectors' reliability. On the other hand, extremely low humidity can lead to the accumulation of static electricity, which can discharge and damage sensitive electronic components.

To understand how humidity affects Board to Board Power Connectors, it is essential to consider the materials used in their construction. Connectors are typically made from metal and plastic components, both of which react differently to humidity. Metal contacts can corrode over time in humid conditions, leading to increased resistance and potential failure. Plastic components, while less susceptible to corrosion, can become brittle and crack in low-humidity environments, which can lead to mechanical failure of the Board to Board Power Connectors.

Manufacturers of Board to Board Power Connectors employ various strategies to mitigate the effects of humidity. These include the use of corrosion-resistant materials, such as gold-plated contacts, which offer superior resistance to oxidation and corrosion. Additionally, some connectors are equipped with protective coatings or housings that shield the internal components from moisture. These designs help to maintain the integrity of the connectors in high humidity conditions.

Testing the reliability of Board to Board Power Connectors under different humidity conditions is crucial. Rigorous testing involves subjecting the connectors to controlled environments with varying levels of humidity, ranging from extremely dry to very humid. These tests help to determine the operational limits of the connectors and identify any potential weaknesses that may arise under specific humidity conditions.

Moreover, the design of the connector plays a significant role in its performance under varying humidity conditions. Connectors with well-sealed interfaces and robust construction are better equipped to handle the ingress of moisture and maintain reliable contact between the boards. However, even with these design enhancements, it is crucial to monitor and control the environmental conditions in which the connectors are used to ensure their longevity and performance.

In conclusion, the reliability of Board to Board Power Connectors is significantly influenced by humidity levels. While connectors can be designed and manufactured to withstand a range of humidity conditions, it is essential to understand the specific requirements of the application to select the most suitable connector. By doing so, manufacturers can ensure the continued performance and reliability of electronic systems in diverse environments, thereby minimizing the risk of failure and downtime.

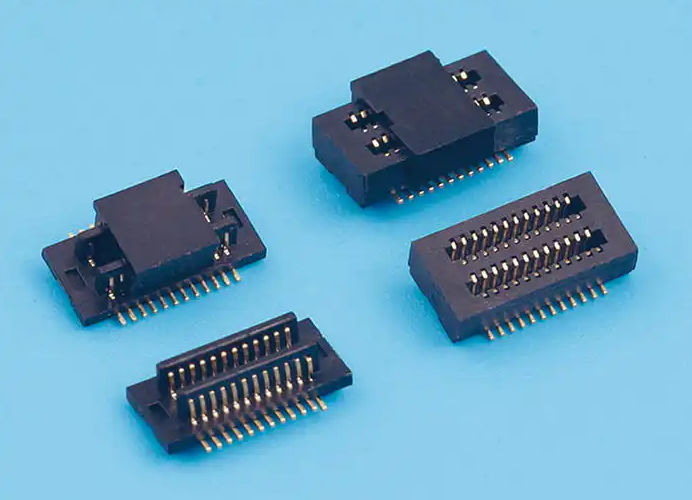

1、CKT: 2*5Pin to 2*40Pin

2、Current rating: 0.5A AC/DC

3、Voltage rating(max): 100V, AC/DC

4、Working Temperature: -25C~ +85C,

(Including temperature rise in applying electrical current)

5、Contact resistance: value s20mΩ

After environmental testing s40mΩ

6、Insulation resistance: 21000MΩ

7、Withstand voltage: 200VAC(rms)

8、Applicable PCB board thickness: 1.6mm to 2.0mm