Injection color masterbatch offers several benefits to manufacturers looking to produce colored plastic products. By providing a concentrated blend of pigments or dyes, additives, and a polymer base, it simplifies the coloring process while enhancing the final product’s performance. This article explores some of the primary advantages of using injection color masterbatch in plastic production.

One of the main benefits of using masterbatch is its ability to offer consistent and uniform coloring. The colorants in the masterbatch are thoroughly blended with the base resin, ensuring that the final plastic product has a consistent color throughout. This is particularly important in industries where aesthetic quality is a priority, such as in the production of consumer goods, automotive parts, or packaging materials.

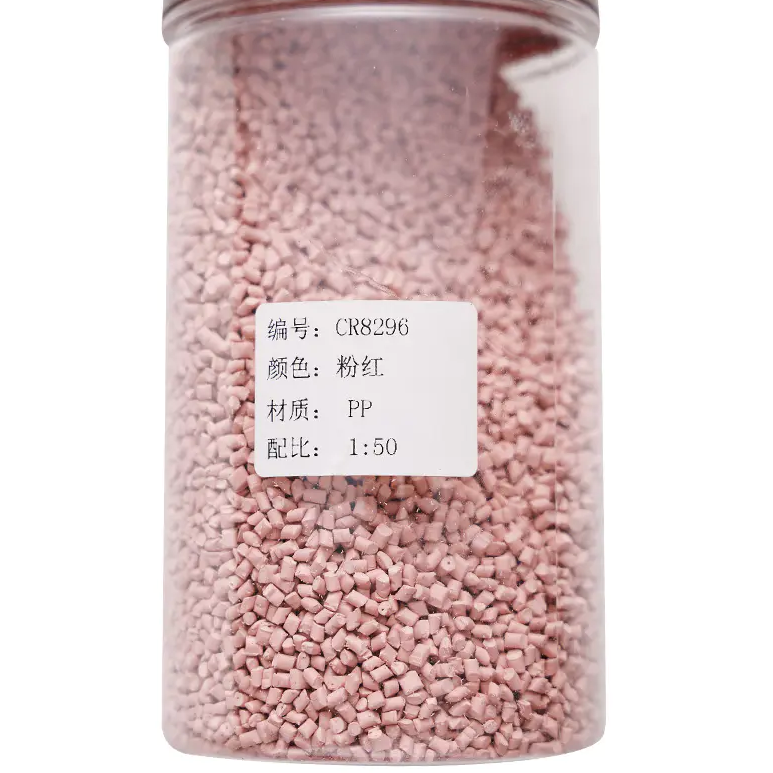

Another advantage is the cost-effectiveness of using injection color masterbatch. Masterbatches are highly concentrated, meaning manufacturers only need to use a small amount to achieve the desired color. This reduces the amount of raw materials required, leading to cost savings. Additionally, since masterbatch is easy to handle, there is less waste and fewer chances for contamination during the coloring process, which further improves overall cost efficiency.

The use of injection color masterbatch also enhances the versatility of plastic products. In addition to providing color, masterbatches can include various additives to improve the physical properties of the final product. For example, UV stabilizers can be added to protect the plastic from fading due to exposure to sunlight, or flame retardants can be incorporated for safety purposes. These customizations allow manufacturers to tailor their products to meet specific performance requirements.

Moreover, injection color masterbatch is compatible with a wide range of polymers, which makes it suitable for various applications. Whether producing products for food packaging, electronics, or automotive components, masterbatches can be used to achieve the desired color and properties, making them a flexible solution for many industries.

In conclusion, injection color masterbatch provides numerous benefits to manufacturers, including consistent coloring, cost savings, versatility, and the ability to enhance product performance. Its wide-ranging applications and customizable options make it an essential tool in modern plastic production.