In the world of manufacturing, efficiency and cost-effectiveness are key considerations. The Replaceable Alloy Drill has emerged as a practical solution for industries that require precision drilling without frequent tool replacements. Unlike traditional solid drills, this type of drill features an interchangeable cutting tip, which allows operators to replace only the worn-out section rather than the entire tool.

One of the primary advantages of using a replaceable alloy drill is its ability to reduce downtime. Instead of halting production to change full drill bits, workers can simply swap the worn tip, keeping the machining process uninterrupted. This feature is particularly useful in industries that require high-volume drilling operations, such as metalworking and construction.

Additionally, the material composition of the replaceable alloy drill ensures durability and resistance to wear. Many of these drills are designed with heat-resistant coatings and tough alloy structures, making them suitable for working with a variety of materials, including stainless steel, aluminum, and composites. The ability to maintain sharpness over extended periods further enhances their efficiency.

As industries continue to seek cost-saving solutions without compromising quality, the replaceable alloy drill remains a valuable tool. Its practical design, combined with long-term usability, makes it an essential component in modern machining processes.

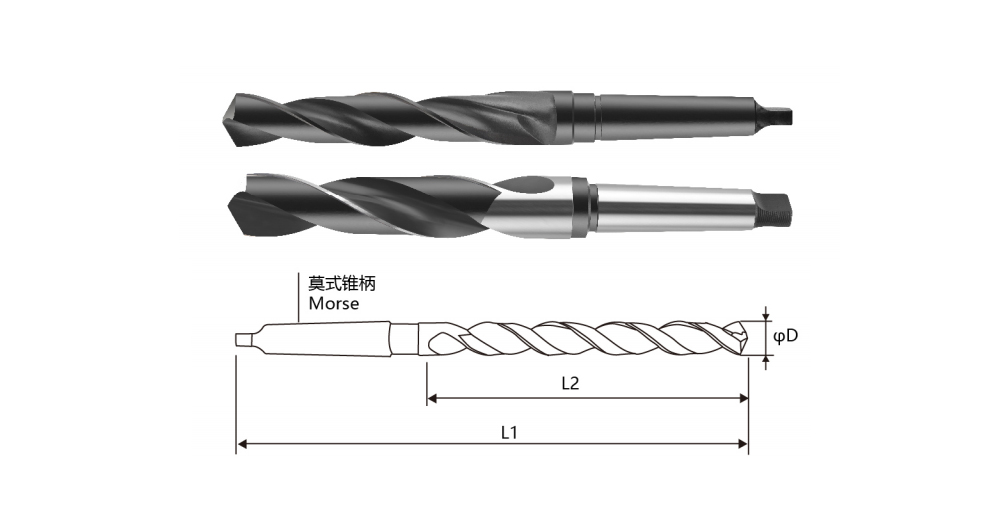

DIN345 4341/6542 tapered shank twist drill is a special drill for metal processing. It is usually made of high-quality 4341 or 6542 high-speed steel materials, which have good hardness and wear resistance, and are suitable for processing a variety of metal materials.