The printing of decorative patterns, patterns, or text on packaging is referred to as printed packaging. A web guiding system is used to automatically guide any type of flexible printing material, regardless of width, load, or seed. They have a wide range of applications for all types of flexible printing, packaging, and converting machines, tracking roller assembly, rotogravure printing machines, lamination machines, Flexo printing machines, coating machines, winding rewinding machines for inkjet printers, are all available. Arise has been providing accurate web guide system for the printing and packaging industries as one of the most professional web guide machine manufacturers.

Advantages of Web Guiding System For Printing Machine

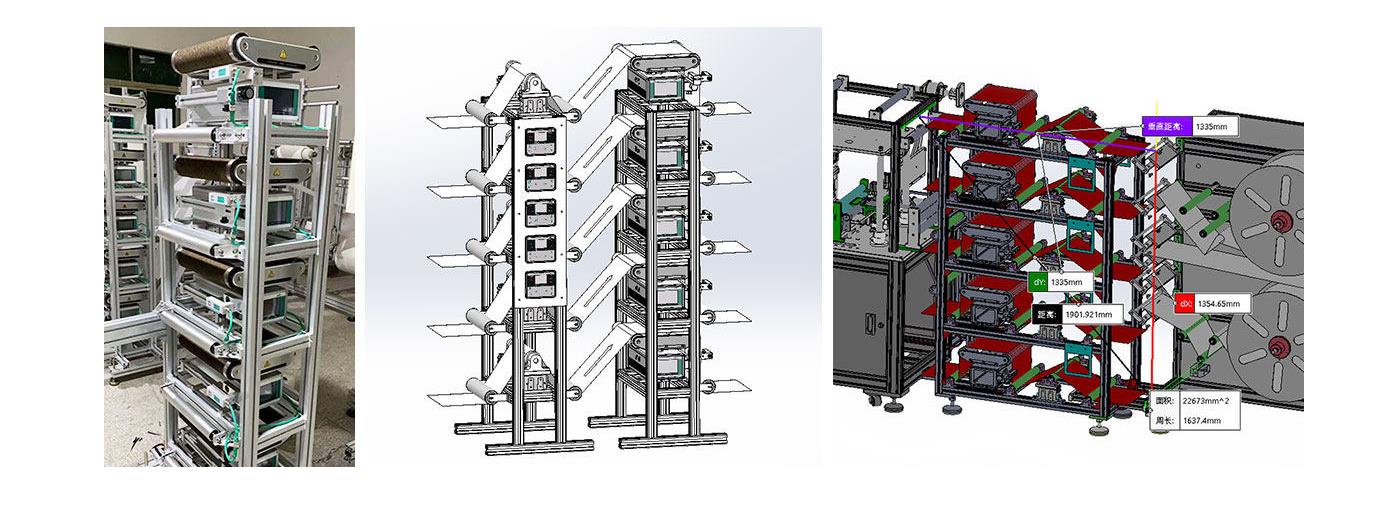

This is a displacement guide system that can quickly correct high-frequency feed errors during the stroke process. Highly compact frame-type rectification with integrated operation and remote control technology, capable of guiding coil position under conditions of minimum inlet and outlet span, with good dynamic response and high execution precision.

1. Three operation modes are supported: edge-following, line-following, and center-alignment.

2. Photoelectric sensor, ultrasonic transducer, and CCD sensor support.

3. Intelligently detect sensor parameters; in most cases, no need to correct the sensor.

4. Control system for printing machines with web guide controller.

5. Automatic travel measurement eliminates the need to mechanically limit the switch.

6. No overshot integral variable PI algorithm, high accuracy, quick response, and low error.

7 Analog quantity transducer signal, 12bit AD sampling, 700000 times per second.

8. A DC servo motor is used to move the ball screw.

9. Power-down memory of all system parameters at any state.

10. Save 10 groups of parameters from different materials for easy and efficient material switching.

11. Support Modbus and PLC/Human-computer networking control.

Why Choose Arise Web Guiding System For Printing Machine

Arise is dedicated to the design and development of a truly innovative and practical coil rectification control system for the continuous and precise control of various production processes in the printing and packaging materials manufacturing process. Strip material types reduce waste and downtime, ensuring that the machine functions properly, lowering production costs, and improving product quality and productivity.

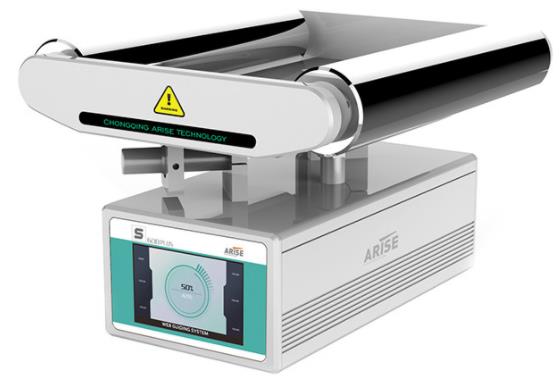

Arise is the culmination of advanced technology that provides stable, accurate corrective performance via a simple, user-friendly interface. The system’s functions are precisely controlled by microcomputer digital and touch controllers. The all-in-one web guiding machine provides several detection methods, including edge guide, line guide, and center/alignment guide. Depending on the materials tested, various sensors such as ultrasonic, infrared, and photoelectric can be used. The drive system is driven by a servo motor, and the drive stroke is strictly proportional to the offset of the coil, ensuring faster and more accurate response of the entire system.

In the printing and packaging industries, the Arise web tension controller has a wide range of applications. The precision of coil tension control is becoming increasingly precise as automation advances. Arise achieves true constant tension control through a precise detection and control system.