In the rapidly evolving landscape of data storage technology, NVMe SSD manufacturers face a significant challenge: ensuring that their products are compatible with a wide range of systems and devices. Compatibility is crucial for the success of any NVMe SSD manufacturer, as it directly impacts the user experience and the market reach of their products. This article delves into the strategies employed by NVMe SSD manufacturers to guarantee compatibility across different platforms.

The journey to compatibility begins with a deep understanding of the market and the diverse needs of consumers. NVMe SSD manufacturers must stay abreast of the latest technological advancements and industry standards to design products that can integrate seamlessly with various operating systems, hardware configurations, and software applications. This requires a proactive approach to research and development, where manufacturers invest in staying informed about the evolving requirements of their target markets.

One of the key strategies employed by NVMe SSD manufacturers to ensure compatibility is adherence to industry standards. By following the guidelines set forth by organizations such as NVM Express Inc., manufacturers can create products that meet the expectations of both hardware manufacturers and end-users. This standardization ensures that NVMe SSDs can be used in a multitude of devices without the need for additional modifications or drivers.

In addition to adhering to standards, NVMe SSD manufacturers also engage in extensive testing procedures. These tests simulate real-world usage scenarios to identify any potential compatibility issues before the products are released to the market. This rigorous testing process involves compatibility checks with different motherboards, CPUs, and other components to ensure that the NVMe SSD performs optimally in various system configurations.

Another aspect of ensuring compatibility is the development of versatile firmware. Firmware plays a critical role in the interaction between the NVMe SSD and the host system. Manufacturers invest in creating firmware that can adapt to different system requirements and handle a variety of tasks, such as data encryption, error correction, and power management. This adaptability is essential for maintaining compatibility across a broad spectrum of devices.

NVMe SSD manufacturers also prioritize backward compatibility, ensuring that their latest products can work with older systems. This is particularly important in enterprise environments where upgrading all components simultaneously may not be feasible. By maintaining backward compatibility, manufacturers can extend the life cycle of their products and cater to a wider customer base.

Collaboration with other industry players is another strategy that NVMe SSD manufacturers employ to enhance compatibility. By working closely with motherboard manufacturers, system builders, and software developers, they can identify potential issues early in the development process and address them proactively. This collaborative approach not only improves compatibility but also fosters innovation and drives the industry forward.

Finally, NVMe SSD manufacturers must be prepared to provide support and updates post-launch. As new systems and software are released, there may be unforeseen compatibility issues that arise. Manufacturers that offer prompt and effective support can quickly resolve these issues, maintaining the trust and loyalty of their customers.

In conclusion, ensuring compatibility is a multifaceted challenge for NVMe SSD manufacturers. It requires a combination of market insight, adherence to industry standards, rigorous testing, versatile firmware development, backward compatibility considerations, industry collaboration, and post-launch support. By addressing these aspects, NVMe SSD manufacturers can ensure that their products are compatible with a wide range of systems, thereby enhancing their market competitiveness and meeting the needs of their diverse customer base.

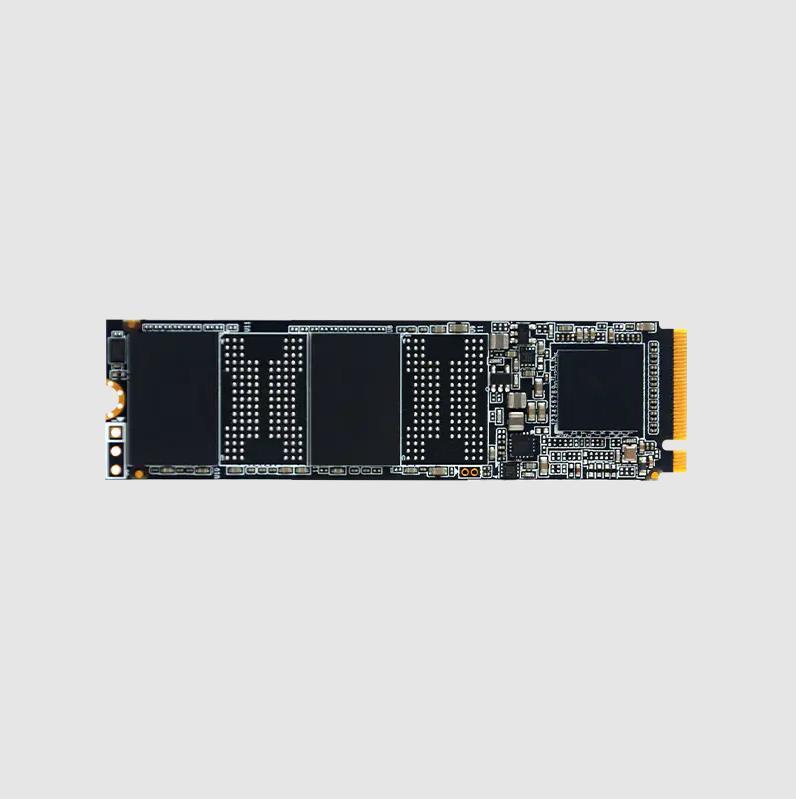

Interface: mSATA

Driver: ATA-8 ACS3

Serial ATA 3.0

Maximum read speed (depending on capacity): 56OMB/s

Maximum write speed (depending on capacity): 480MB/S

Maximum power consumption(depending on capacity): 1.2w

Media type: 3D TLC/QLC

MTBF(hours): 1,000,000

Operating temperature: 0°C-70°C

Storage temperature: -40°C-85°C

Working humidity: 8%-95% non-condensing

Warranty: 3 Years limited warranty