The environmental impact of Aluminum Composite Panel Production Line is an important consideration for manufacturers and consumers alike. As the demand for sustainable materials grows, production lines must adopt practices that minimize their ecological footprint.

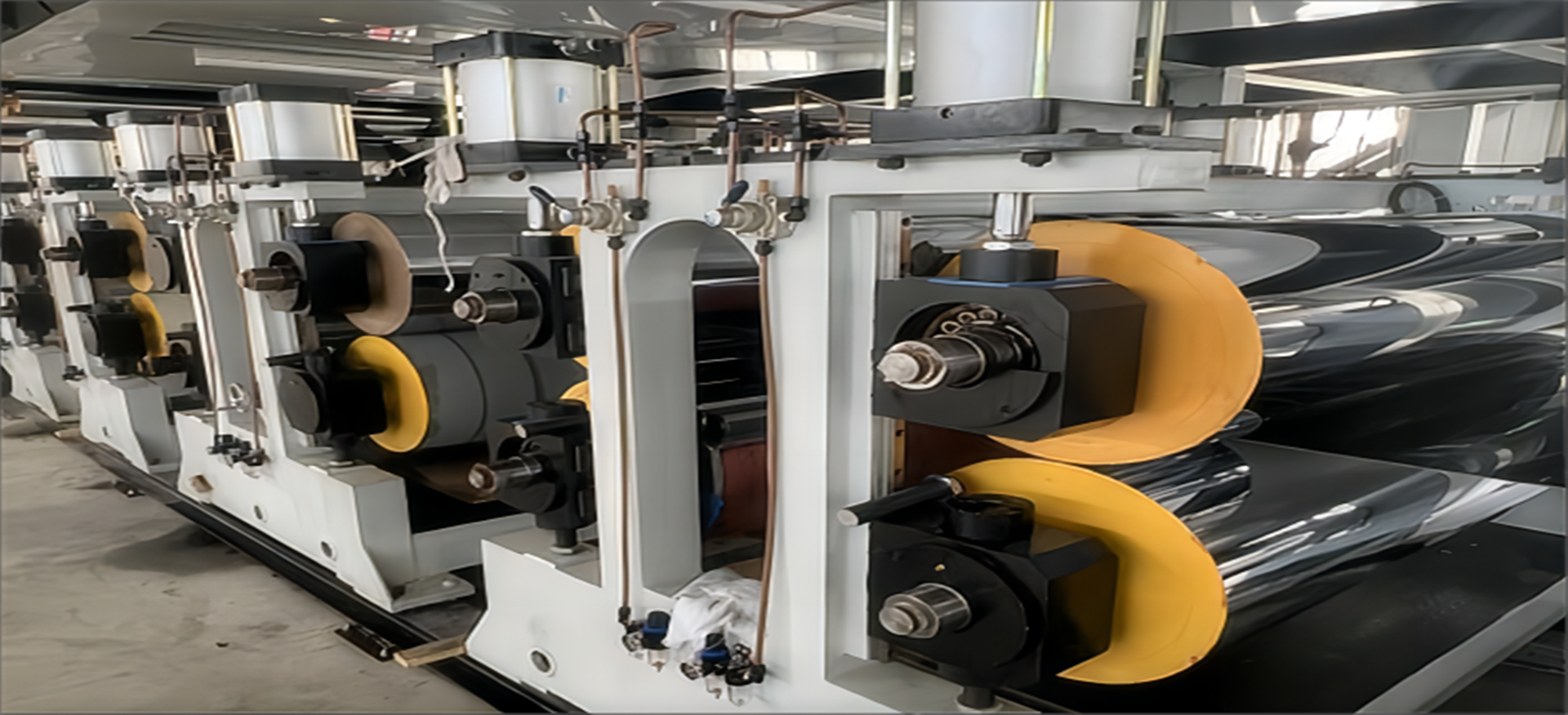

One way to achieve this is by incorporating energy-efficient machinery into the production line. Modern equipment with optimized heat distribution and reduced energy consumption can significantly lower greenhouse gas emissions. Additionally, using renewable energy sources to power production facilities can further enhance sustainability.

Recycling is another key aspect. Aluminum is a highly recyclable material, and many production lines now feature systems that allow for the reuse of aluminum scraps. This reduces waste and conserves natural resources. Efforts are also being made to develop eco-friendly core materials, replacing traditional polyethylene with biodegradable or recycled alternatives.

The water used in the pre-treatment process is another area of focus. Advanced water treatment systems can recycle and purify water, reducing consumption and preventing contamination.

Manufacturers must also consider the end-of-life impact of aluminum composite panels. Promoting recycling programs for used panels can help close the material loop and reduce landfill waste.

By prioritizing environmental considerations, aluminum composite panel production lines can contribute to a more sustainable future for the construction and decoration industries.

https://www.coating-line.com/product/acp-production-line.html

Application of Product and characteristics:

The final product ACP can be widely used in field of construction decoration such as curtain wall, interior and exterior wall of building,ceiling,column,storefront,billboard,exhibition rack,and auto etc.

1.High capacity and various thickness from 1mm to 8mm ;

2.The thickness range of Aluminum coil covers 0.018mm-0.5mm ;

3.Can use recycled PE ;

4.Stable technics and easy operation;