- Hydrotreatment: under a certain temperature and pressure, diesel contact with hydrogen, the sulfur is converted into hydrosulfuric acid, then removed by pickling method. This method can effectively reduce the sulfur content in diesel, However the plantinvestment is large and the energy consumption is high.

- Solvent extraction method: choose an organic solvent that can form a substance with a large solubility with sulfur compounds, such as diphenyl ether, kerosene, etc., mix diesel with the solvent, so that the sulfur compounds are dissolved in the solvent, and then remove by separation and washing method. This method is easy to operate, but solvent recovery is difficult and may introduce new pollutants

- Adsorption method: The use of activated carbon, molecular sieve and other substances with strong adsorption capacity, the sulfur in diesel is adsorbed on its surface, and then it is separated from the adsorbent by desorption or heating desorption method. This method is simple to operate, but the regeneration of the adsorbent requires energy consumption.

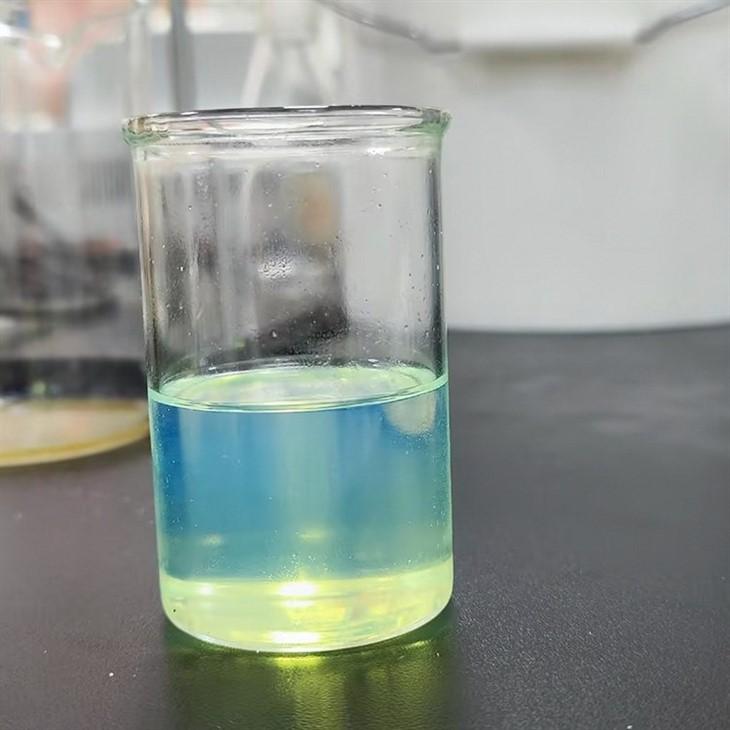

- Oxidation method: The use of ozone, hydrogen peroxide and other strong oxidants, the sulfur oxide in diesel into soluble sulfate or thiosulfate, and then adjust the pH value with lye, so that the sulfur in the form of sodium sulfate or sodium thiosulfate precipitate out. This method can effectively reduce the sulfur content in diesel, but there may be equipment corrosion problems.

- Biodegradation method: The use of microbial biodegradation, the sulfur in diesel fuel into harmless substances. This method is environmentally friendly, but it needs to choose the right kind of microorganisms, and the degradation rate is slow.

How to reduce sulfur content in diesel

Posted 2025-01-04 03:24:39

0

901

Search

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

North America Refractories Market | Key Trends and Industry Innovations By 2032

Executive Summary North America Refractories Market :

The North America refractories market...

Biochip Scanner Market Poised for Significant Growth, Projected to Reach USD 27.36 Bn by 2030

Biochip Scanner Market Poised for Significant Growth, Expected to Reach USD 27.36 Bn by 2030...

Radio-frequency Identification (RFID) Blood Monitoring Systems Market Overview: Growth, Share, Value, Size, and Scope

"Executive Summary Radio-frequency Identification (RFID) Blood Monitoring Systems...

The Essential Guide to Drop Test Machines

In the realm of material testing, the Drop test machine is an indispensable tool for engineers...

《庆余年第二季》:权谋与情感的交织

《庆余年第二季》电影在线观看改编自猫腻的同名畅销小说,延续了第一季的精彩剧情,带领观众进入了更加复杂的权谋斗争和感人至深的情感故事。该剧通过紧张的情节和细腻的人物刻画,再次吸引了观众的目光。...